With the rapid development of electronic technology, the miniaturization and micro-miniaturization of electronic componentsBGAChips with high-density pitch are becoming increasingly common, and the requirements for electronic soldering technology are also getting higher and higherSMTIn processing plants, false welding has always been at the top of the list of defects. False welding can lead to unstable performance of products. False soldering cannot even be carried out subsequentlyICTandFCTThe tests have discovered that this has led to problematic products flowing into the market and even causing huge losses to the brand and reputation. The following is JJYSolder paste manufacturerLet's explain some of the reasons for false soldering:

AboutSMTPatch andDIPThe soldering of the plug-in components is weak. The reasons for this are as follows:

1False soldering caused by poor solderability of components(The solderability of the functional modules is poor);

2,PCBFalse soldering caused by poor solderability;

3False soldering caused by coplanarity;

4False soldering caused by insufficient performance of solder paste(Including the deterioration of solder paste);

5False soldering caused by improper process control;

The definitions of false soldering and false soldering:

False soldering refers to the pins of components, soldering ends,PCBThe solder pad is not soldered sufficiently, and the wetting Angle of the solder at this location is greater than90°And only a small amount of solder wets the pins and solder ends.PCBThe solder pads cause poor contact, resulting in intermittent connection and disconnection.

False soldering refers to the situation where the pins and soldering ends of components are well soldered, and a good solder joint appears to have been formed on the surface, but the solder inside the solder joint is notPCBThe pads do not form a good weld, and when the solder joints are subjected to external force, they can be easily detached from the pads.

These two defects are commonly seen in single-sided copper claddingPCBIn the welding process.

A more detailed analysis of the causes of false soldering and false soldering:

(1)Component soldering ends, pinsPCBOxidation or contamination of the disk leads to poor solderability;

(2)The solder joint positions are contaminated by impurities such as oxides, making it difficult to solder:

(3)The adhesion of the metal electrode at the welding end is poor, or when a single-layer electrode is used, the cap comes off at the welding temperature;

(4)Component/The heat capacity of the pad is large, and the component pins and pads have not reached the soldering temperature,

(5)Improper selection of flux, poor activity or failure of flux, leads to poor wetting of solder joints;

Causes and Solutions of false soldering:

1There is a defect in the pad design. There should be no through holes on the solder pads. Through holes will cause solder loss and result in insufficient solder;The pad spacing and area also need to be standardly matched; otherwise, the design should be corrected as soon as possible.

2,PCBThe board shows oxidation, that is, the solder pads turn black and lose their luster. If there is oxidation, the oxide layer can be removed with an eraser to restore its luster.PCBIf the board is suspected to be damp, it can be dried in a drying oven.PCBIf the board is contaminated with oil stains, sweat stains, etc., it should be cleaned thoroughly with anhydrous ethanol at this time.

3Those printed with solder pastePCBThe solder paste is scraped or rubbed, reducing the amount of solder paste on the relevant solder pads and resulting in insufficient solder. It should be replenished in time.

4,SMD(Surface component)Poor quality, expiration, oxidation and deformation cause false soldering. This is a relatively common reason.

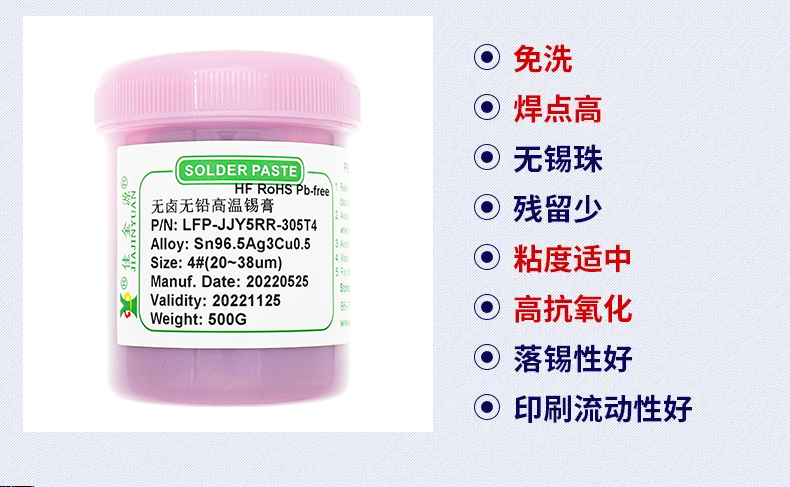

As a 16-year-old veteran solder paste manufacturer, JJY has been committed to the research and development, production and sales of solder paste. Our product quality is stable, with no solder connection, no false soldering, and no monument erection. Residual Wuxi beads, bright and full solder joints, firm welding, and excellent electrical conductivity. If you have any needs, please feel free to contact us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account