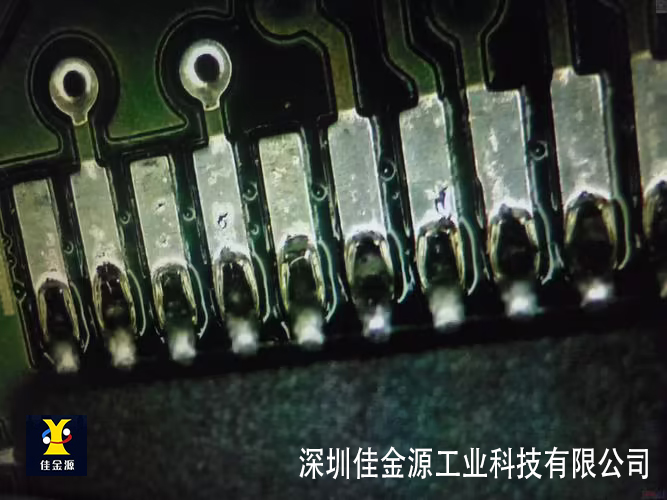

smtIn surface mount technology (SMT) processing, soldering with tin is a crucial step that affects the performance and appearance of circuit boards. However, in actual production, this sometimes occursSolder pasteThe situation of poor soldering, such as insufficient soldering on the solder joint, will be directly reducedsmtThe quality of surface mount technology (SMT) processing. Shenzhen JJY Solder Paste Manufacturer will introduce the following reasons in detail for everyone:

1The wetting performance of the solder paste in the solder paste is relatively poor. Flux paste helps the solder paste form good wetting at the soldering area and improves the soldering efficiency. If the wettability of the solder paste is poor, it will lead to the solder paste not being fully spread and also result in insufficient soldering.

2The activity of the flux in the solder paste is insufficient. Another function of solder paste is to removePCBSolder pad orSMDRemove oxides and impurities from the welding area to ensure the quality of tinning. If the activity of the solder paste is insufficient, oxides and impurities will remain at the soldering area, hindering the wetting and flow of the solder paste, and also causing incomplete soldering.

3The expansion rate of the solder paste in the solder paste is too high. During reflow soldering, solder paste will expand and volatilize. If the expansion rate is too high, voids will form in the solder paste, affecting the uniformity and stability of soldering.

4,PCBSolder pad orSMDThe oxidation at the welding site is severe.PCBorSMDDuring storage or transportation, it may be affected by factors such as air, moisture and dust, leading to surface oxidation. The oxidized surface is not conducive to the wetting and adhesion of solder paste, and it will also cause incomplete tin coating.

5The amount of solder paste at the solder joint is insufficient. If sufficient solder paste is not provided during the printing or dispensing process, the solder joint area will lack the necessary filling material, which will also result in incomplete soldering and the appearance of voids.

6If only some solder joints show incomplete soldering, it might be due to the solder paste not being thoroughly stirred before use. Solder paste is a mixture composed of flux paste and tin powder. After long-term storage, it may experience sedimentation or stratification. If not stirred thoroughly, the solder paste and tin powder will not be evenly distributed, causing local defects during printing or dispensing.

7The preheating time is too long or the preheating temperature is too high during reflow soldering. Preheating is to makePCBandSMDGradually increase the temperature to avoid thermal shock caused by excessive temperature differences. However, if the preheating time is too long or the preheating temperature is too high, the solder paste in the solder paste will fail prematurely or evaporate completely, losing its wetting and deoxygenation functions, and also resulting in incomplete soldering.

That's all.smtAnalysis of the reasons for insufficient solder coating on solder paste, hoping to be helpful to everyone. If you have any other questions, please feel free to consult JJY Solder Paste Factory for more informationSMTProfessional solutions for solder paste.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account