inSMTDuring surface mount technology (SMT) processing, some processing defects and defects may occur.Solder pasteDefects are one of them, but they can be avoided through some methods. So, what should we do? The following is a brief description of Shenzhen JJY Solder Paste Manufacturer:

1.SMTHow to deal with solder paste defects in solder paste:

SMTIn a turnkey project, the longer the operator waits after discovering a printing error after the solder paste is printed, the more difficult it is to remove the solder paste. If any problem is found, the improperly printed board should be immediately placed in the soaking solvent, as the solder paste can be easily removed before it dries.

Ii.SMTHow to avoid solder paste defects in surface mount technology (SMT) processing:

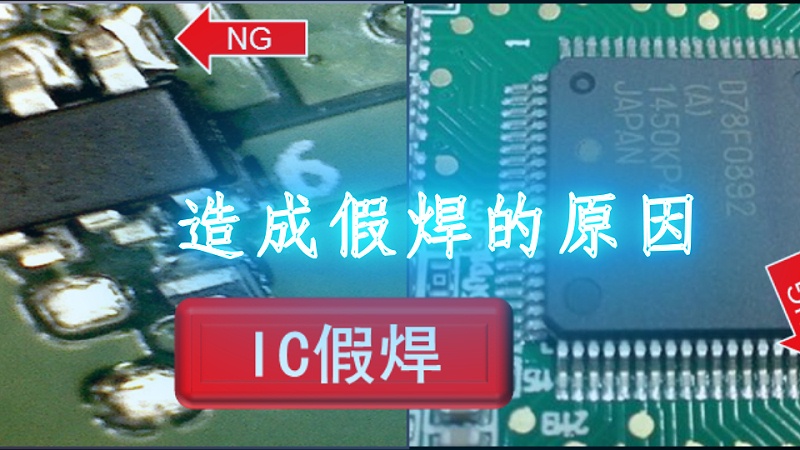

During the processing of printing on a fully automatic printing machine, the printing cycle is fixed in a specific pattern. Make sure the template is located on the solder pad, which can ensure the cleanliness of the solder paste printing process. For micro templates,If damage occurs between the thin pins due to the bending of the template cross-section,It may lead to printing defects and short circuits.

JJY is a well-established solder paste manufacturer with a history of sixteen years, always dedicated to the research and development, production and sales of solder paste. Our product quality is stable, with no solder connection, no false soldering, and no monument erection. Residual Wuxi beads, bright and full solder joints, firm welding, and excellent electrical conductivity. If you have any needs, please feel free to contact us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account