With the rapid development of the electronics industry, high integration and high reliability have become the new trend in the industry. Driven by this trend,SMT(Surface mount technology) has also been further promoted and developed in China. Many companies have widely applied it in production and research and developmentSMTProcess and surface mount componentsSMC/SMD" Therefore, the welding process inevitably makes extensive use of reflow soldering machines.reflow soldering" Shenzhen JiajinSource solder paste manufacturerHere are some experiences and opinions on the reflow soldering temperature curve:

The key steps for setting the reflow soldering temperature curve

1Understand the working principle of reflow soldering:

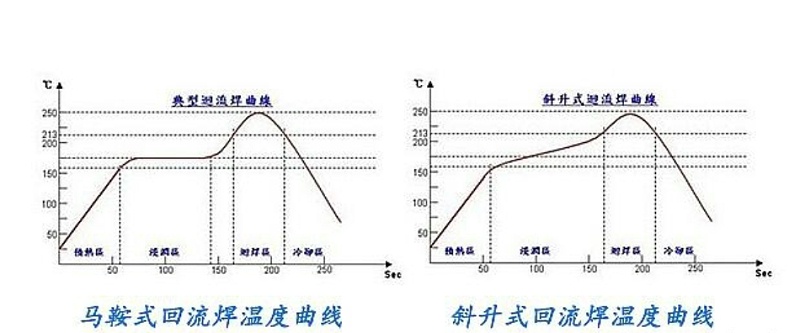

The temperature curve reflectsPCBThe temperature changes in different areas within the reflow soldering machine.

The correct temperature curve can ensure the welding quality and product reliability.

2Analyze each stage of the temperature curve:

Heating zone (drying zone) : The solvent and gas evaporate, and the flux begins to act.

Insulation zone: PreheatingPCBAnd components, prevent thermal shock.

Welding area: The solder paste melts to form a weld point.

Cooling zone: The weld point solidifies and the welding is completed.

3Determine the key parameters:

The highest temperature point and its corresponding time.

PCBThe time intervals through each sensor.

ConsiderPCBThe differences in material and heat absorption capacity.

4Adjust the speed of the heater and the mesh belt:

According to the position of the sensor andPCBSet the temperature of each heater at the moving speed.

The speed of the mesh belt needs to match the time required by the standard curve.

5Actual testing and correction:

Actual welding tests need to be conducted after the initial Settings.

Observe the data of the solder joint quality and temperature curve, and make necessary fine-tuning.

Precautions

Environmental factors influence: Changes in environmental temperature can have an impactPCBThe temperature curve of the plate. Therefore, the temperature and humidity control in the production workshop is also very important.

Equipment maintenance and calibration: Regularly maintain the reflow soldering machine and calibrate the sensors to ensure that the equipment is in the best working condition.

As a 16-year-old veteran solder paste manufacturer, JJY has always been committed to the research and development, production and sales of solder paste. The quality of the solder paste is stable, without solder bonding, false soldering or establishing a reputation. Residual Wuxi beads, bright and full solder joints, firm welding, and excellent electrical conductivity. If you have any needs, please feel free to contact us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account