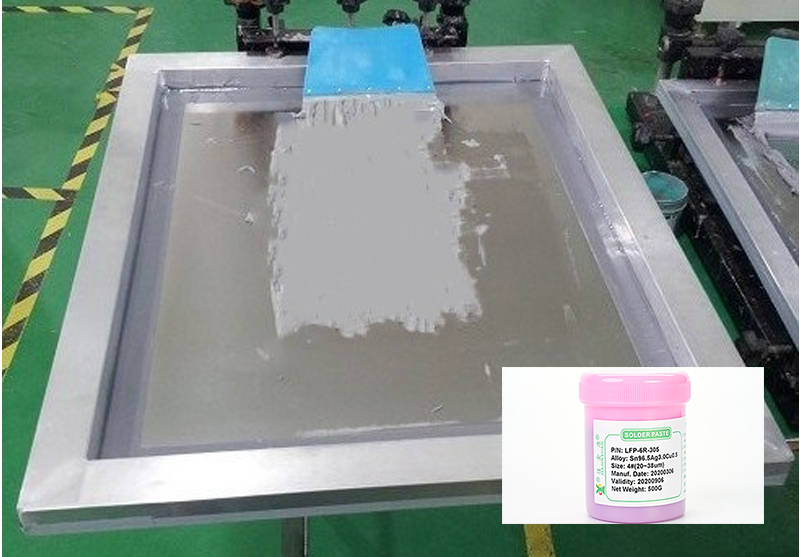

Solder pastePrinting issmtThe key process in surface mount technology (SMT) processing directly affects the quality of solder joints and the performance of electronic components. Sometimes, the printed steel screen gets clogged. Why is that? Today, Shenzhen JJY Solder Paste Manufacturer will analyze it together with everyone:

1The steel mesh was not cleaned thoroughly, with dust or debris. Once it comes into contact with solder paste, they will "clump together", causing the steel mesh to get clogged.

2The opening design of the steel mesh is unreasonable. If the mesh is too small and there are too many burrs, it will cause the solder paste to be unable to be downloaded, thus resulting in mesh blockage.0.4pitchThe openings of the steel mesh are relatively small. If there are many burrs at the edge of the steel mesh, resulting in poor tin plating, it will also get clogged.

3The solder paste blocking of the steel mesh is also related to the working temperature. The working environment can be taken into consideration.

4The composition of solder paste will constantly change during use,The most obvious one is the change in viscosity.When the temperature is relatively high,Flux evaporates relatively quickly,When the humidity is high,The water absorption of solder paste will be more prominent again,All of these will cause changes in the viscosity of the solder paste,This affects its surface tension, and the change in tension will lead to the change in the situation of net disengagement.

5The viscosity of the selected solder paste, the particle size of the tin powder, the material of the scraper, the pressure during operation, the pressure of the pressure plate and the time of plate removal, etc., can also cause the steel mesh to be clogged.

Shenzhen JJY Industrial Technology Co., Ltd. mainly engages in the production and operation of:SMTSolder paste manufacturers of solder paste, syringe solder paste, lead-free solder wire, wave soldering bar, automatic soldering wire, etc.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account