Indispensable soldering materials in the electronic assembly industrySolder pasteInsmtIt plays a very important role in surface mount technology (SMT) processing. Due to the different densities of various substances, various metal components and the main components of some fluxes precipitate at the bottom during storage. Therefore, it is necessary to stir before use. Now, let's have JJY solder Paste Manufacturer explain it to you:

1"Warming up"

Solder paste is usually refrigerated in the refrigerator at a temperature of2℃~10℃It's best. Therefore, when taking solder paste out of the refrigerator, its temperature is much lower than the room temperature. If the bottle cap is opened without "warming up", it is easy for the water vapor in the air to condense and adhere to the solder paste. When passing through the reflow oven, the water will rapidly vaporize due to the strong heat, causing a "tin explosion" phenomenon, generating solder beads, and even damaging the components.

The way to warm up the solder paste: Without opening the bottle cap, let it thaw naturally at room temperature.

Warming time:4About an hour.

Note:

①Never open the bottle cap without sufficient "warming up".

②Do not shorten the "warming up" time by heating.

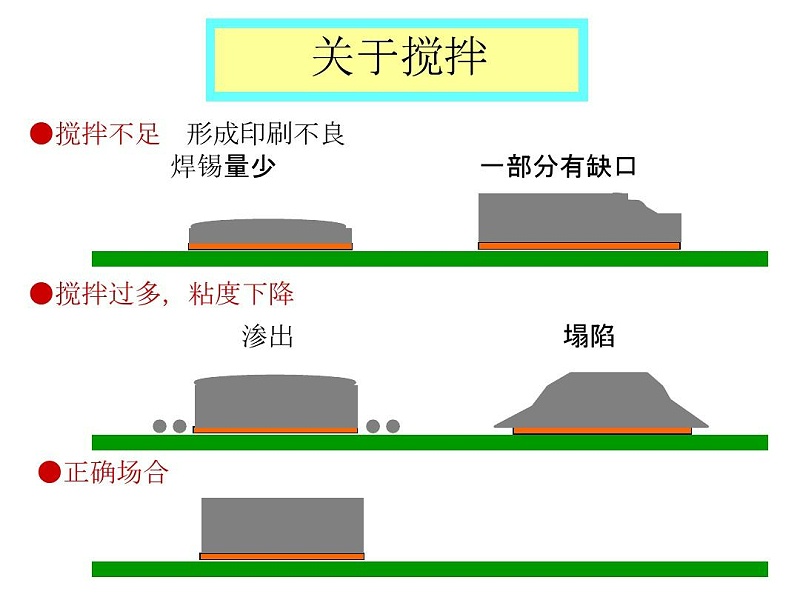

2Stir

After the solder paste has "warmed up", it should be thoroughly stirred before use.

Objective: To ensure uniform distribution between flux and tin powder and give full play to various properties;

Stirring method: Both manual stirring and machine stirring are acceptable.

Stirring time: Manual1~3Minutes, machine:1~2Minutes;

The determination of the stirring effect: Use a spatula to scrape up part of the solder paste. When the spatula is tilted, if the solder paste can slide smoothly, the requirement can be met.

The appropriate stirring time varies due to factors such as the stirring method, device and ambient temperature. It should be determined through more experiments in advance.

Shenzhen JJY Industrial Technology Co., Ltd. is located in Longhua, Shenzhen. It mainly produces and operates lead-free solder paste, lead-free high-temperature solder paste, lead-free medium-temperature solder paste, lead-free low-temperature solder paste, etc. If you have any needs, please feel free to contact us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account