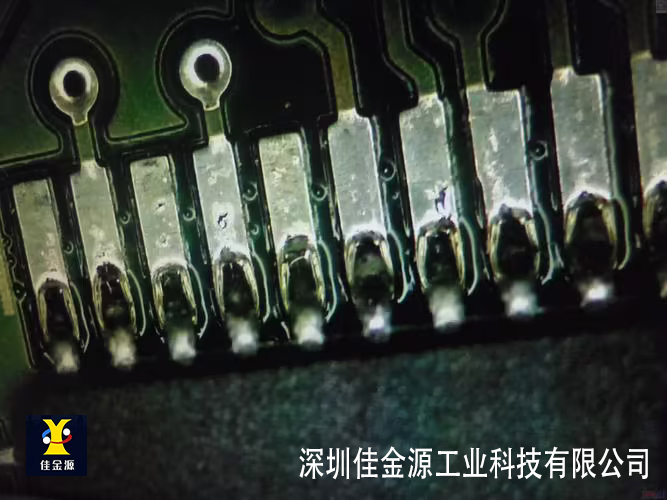

Shangxi isSMTOne of the very important processing techniques in surface mount technology (SMT) production is incomplete solderingSMTThe more common processing defects in processing. For electronic processing factories, any defective processing phenomenon needs to be taken seriously. Only by ensuring that no defective phenomena occur in every link can the best products and services be provided to customers. So, what causes the tin coating to be not full? Below, JJY Solder Paste Manufacturer will share with you the reasons for the occurrence of insufficient solder filling during the surface mount technology (SMT) processing:

1If it is usedSolder pasteIf the wetting performance of the solder paste does not meet the standard, proceedSMTWhen performing surface mount soldering, there will be a situation where the solder is not fully applied.

2If the flux in the solder paste is not active enough, it will be unable to better remove the oxidized substances on the solder pads, which will also have a certain impact on soldering.

3IfSMTWhen processing, if the surface tension of the flux is very high, the phenomenon of easy voids will occur.

4If the solder pad orSMDIf there is a relatively severe oxidation phenomenon at the welding site, it will also affect the tinning effect.

5If the amount of solder paste used during soldering is too small, it will also result in insufficient soldering, causing voids.

6If the solder paste is not thoroughly stirred before use and the flux and solder powder are not fully mixed, it will also cause the solder at some solder joints to be not full.

In progressSMTDuring surface mount technology (SMT) processing, avoid the above-mentioned situations that may lead to insufficient tin filling, thereby effectively avoiding the problem of insufficient tin filling to the greatest extent. If you have any further needs or technical questions regarding soldering, please follow the online message of JJY Solder Paste Factory to interact with us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account