SMTPatchSolder pastePrinting is a relatively precise processing technique, inSMTIt holds an important position in surface mount technology (SMT) processing and will have a direct impactSMTThe quality of processing There are also many points to note in the processing and production of solder paste printing. If not paid attention to, some defects that affect the processing quality of the product may occur. Shenzhen JJY Solder Paste Manufacturer briefly introduces the precautions in solder paste printing for everyone:

1Confirm before printing and inspect the required steel mesh.PCBAWhether the solder paste and the rest of the tooling fixtures match;

2Check whether there are any foreign substances such as tin slag remaining in the mesh holes of the steel mesh,Whether the board surface is cleaned thoroughly;

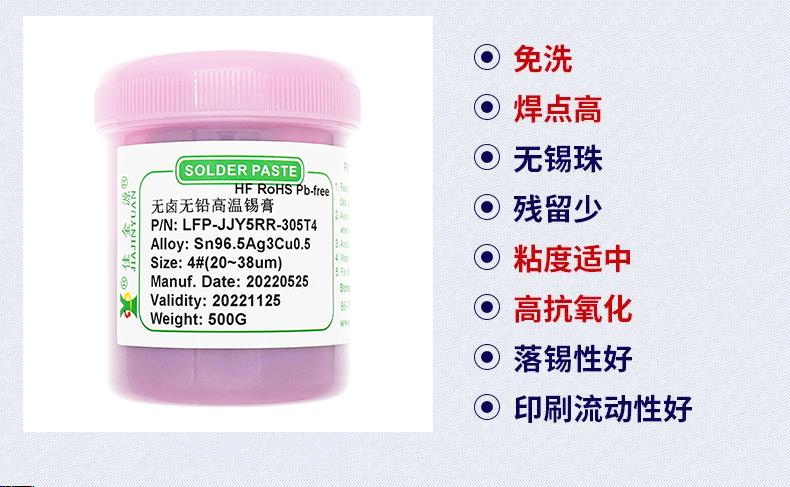

3Confirm whether the brand and model of the solder paste used are correct;

4Confirm the warming up and stirring time (warming up4HStir5Minutes;

5At the beginningSMTBefore the surface mount technology (SMT) processing, the engineer places the steel mesh and fixtures on the printing machine, adjusts all parameters, and ensures that the program name matches the actual required model. The Angle of the scraper is60-70The degree, printing speed is40-80MM/Seconds, the pressure of the scraper is3.0-5.0kgf/cm2The demolding speed is0.3-2.0mm/sec.The automatic wiping frequency is3-5PCS/1This time.

6Pre-input inspectionPCBACheck for deformation, damage, foreign matter or oxidation. Wipe the surface with a lint-free cloth.

7For products of poor quality, you can first scrape off the solder paste on the board surface with a soft scraper, then recycle the solder paste with an empty bottle labeled in red, finally clean the residual solder paste on the board surface and in the holes with board cleaning water, and finally blow it clean with a tool.

8The cleaned substrates are placed separately and an oil-based pen is used to mark the edges of the boards.△Mark to be madeIPQCConfirmOKThen they are all placed in the oven for baking.

9Manually clean the steel mesh. When wiping, the machine should be in manual mode. Use a lint-free paper dampened with a little cleaning solution to wipe from the bottom of the steel mesh. Wipe it clean and then use a tool to blow the remaining solder paste in the hole from bottom to top. Depending on the quality condition, if it is continuous3For the first time, if any problem occurs, immediately feed it back to the engineering department for adjustment. Only after the adjustment is completed can normal production resume.

10When placing good products on the shelves, they should be placed in layers. Fill in the machine type and work order status completely on the process marking card.

11,SMTPrinted during processingPCBAThe accumulation time should not exceed1Hours;

12When adding solder paste, the rolling amount of the squeegee should be taken as the standard, and the solder paste that is missed on both sides of the squeegee should be promptly collected into the squeegee.

13When working, the lighting should be turned off in time.

14Engineering personnel regularly inspect the wear condition of the blades and generally replace them once every half year.

Shenzhen JJY Industrial Technology Co., Ltd. mainly engages in the production and operation of:SMTSolder paste manufacturers of solder paste, syringe solder paste, lead-free solder wire, wave soldering bar, automatic soldering wire, etc.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account