inSMTIn surface mount technology (SMT) processing, some customers have requirements for the glossiness of solder joints. Solder joints with higher glossiness offer a better appearance experience. The glossiness of solder joints andSMTThere are many aspects related to the patch. Now, let's talk about Shenzhen JJYSolder paste manufacturerLet me give you a brief introduction:

1If the tin powder in the soldering process oxidizes, it will affect the gloss of the solder joint.

2The glossiness is also related to whether additives that can produce a matting effect are added to the flux.

3InSMTIn the reflow soldering process of surface mount technology (SMT) processing, the preheating temperature is relatively low, which leads to the retention of organic residues that are difficult to evaporate on the surface of the solder joints, and also affects the gloss of the solder joints.

4After welding is completed, if rosin or resin-like residues remain on the surface of the weld points, it will also affect the gloss of the weld points.

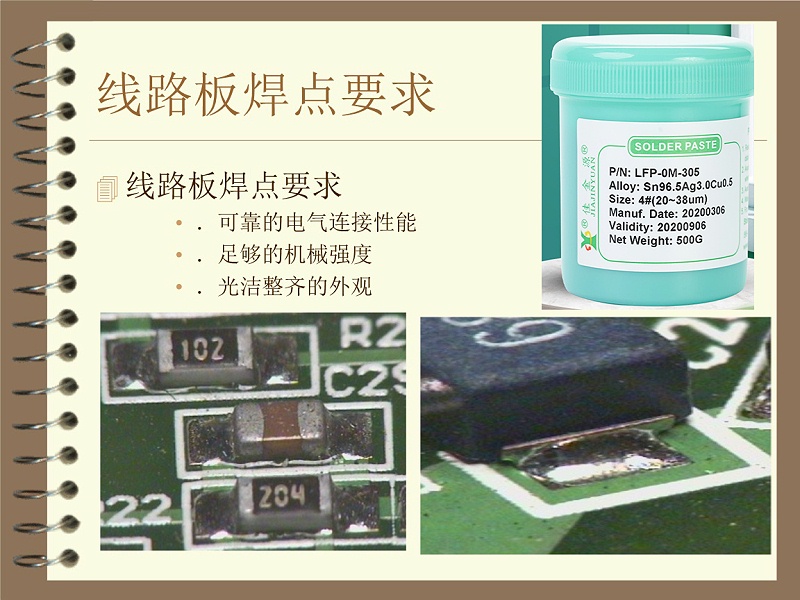

5Apart from the production and processing techniques, the selection of raw materials also has a significant impact on the glossiness of the solder joints. The glossiness of the solder joints processed with silver-containing and non-silver-containing solder pastes is different. If there are requirements for the glossiness of the solder joints, it is necessary toSMTClear requirements should be put forward before the surface mount technology (SMT) processing is carried out, so as to facilitate the selection of production raw materials and processes.

Shenzhen JJY Industrial Technology Co., Ltd. mainly engages in the production and operation of:SMTSolder paste manufacturers of solder paste, syringe solder paste, lead-free solder wire, wave soldering bar, automatic soldering wire, etc.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account