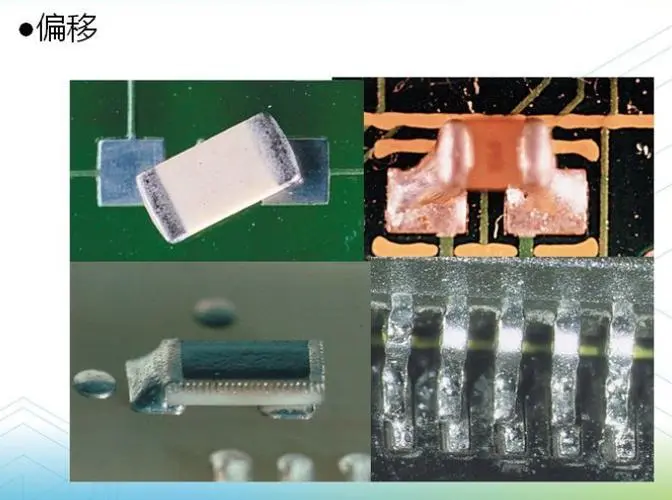

inSMTDuring the production and processing of surface mount technology (SMT), the displacement of components is a common quality issue. With the advancement of technology and the increasingly refined demands of consumers for electronic products,SMTSurface mount technology has been widely applied due to its high precision and efficiency. However, even in such advanced production processes, the problem of component displacement still occurs from time to time. Then, it causesSMTWhat exactly are the reasons for the displacement of components in surface mount technology (SMT) processing? Next up is Shenzhen JJYSolder paste manufacturerLet's talk about it

First of all, the air pressure of the suction nozzle of the surface mount technology (SMT) machine is an important factor affecting the position of components. If the air pressure is not adjusted in time and is too low, it may cause the components to shift during the surface mount process.

Secondly, the content of flux is also a key factor that needs to be paid attention to. Excessive flux content during reflow soldering may cause excessive flux flow, which in turn may lead to the displacement of components.

Besides,Solder pasteThe stickiness of the product also has a direct impact on the positional stability of components. If the viscosity of the solder paste is insufficient, the components are prone to displacement during movement due to oscillation, shaking, etc.

Meanwhile, the usage time of solder paste is also a factor that cannot be ignored. Once the solder paste exceeds its effective service life, the flux may deteriorate. This will affect the quality of surface mount soldering and cause the components to shift.

In addition, the components areSMTDuring the movement process after printing and mounting, if the components are shaken or an incorrect transfer method is adopted, it may also cause the displacement of the components.

Finally, mechanical issues with the surface mount technology (SMT) machine may also lead to inaccurate positioning of components, thereby causing displacement.

To sum up,SMTThe causes of component displacement in surface mount technology (SMT) processing are diverse. They include improper setting of process parameters, issues related to material quality and service life, as well as mechanical failures and improper operation. Therefore, in actual production, we need to comprehensively consider various factors, reduce the occurrence rate of component displacement through refined process control and strict quality management, and ensureSMTThe quality and efficiency of surface mount technology (SMT) processing.

As a 16-year-old veteran solder paste manufacturer, JJY has been committed to the research and development, production and sales of solder paste. The solder paste we produce is of stable quality, without solder connection, false soldering or monument erection. No residue, Wuxi beads, bright, full, firm solder joints with excellent electrical conductivity. If you have any needs, please feel free to contact us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account