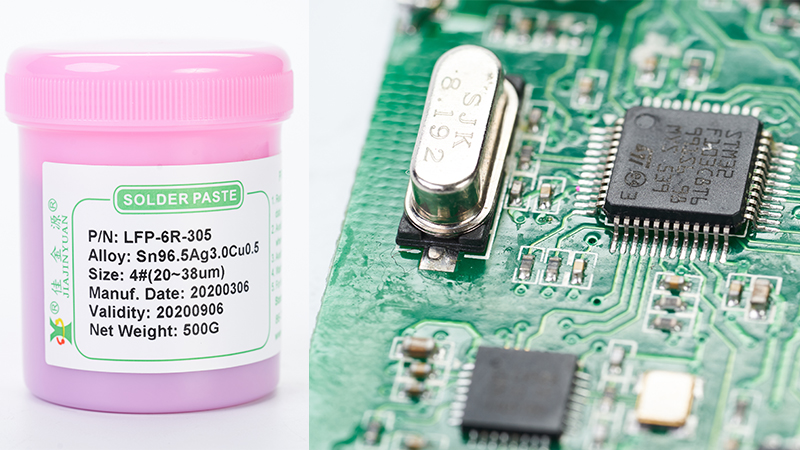

SMTAn indispensable process material in the reflow soldering process of surface mount technology (SMT) processingSolder pasteIt is a paste welding material uniformly mixed with alloy powder and paste flux carrier. First of all, the function of solder paste is at room temperature,Because solder paste has a certain degree of viscosity, it can beSMTThe surface mount components are temporarily fixed in their corresponding positionsPCBAt the pad position. When heated to a certain temperature, the alloy powder in the solder paste melts at high temperatures to form a liquid, and the liquid solder wets the solder ends of the componentsPCBThe pad is connected, and the soldered end of the cooling element is connected toPCBThe solder pads are connected to form solder joints for both electronic and mechanical connections. The printability of solder paste and the solderability of the soldered parts and pads have a direct impactSMTThe key factors of surface mount technology (SMT) processing quality. Solder paste isSMTThe important process materials in surface mount technology (SMT) processing, thenSMTWhat are the technical requirements for the use of solder paste in surface mount technology (SMT) processing plants? Next, let's have Shenzhen JJY Solder Paste Manufacturer explain it to you:

I. Before using the solder paste

1The solder paste has arrivedSMTThe storage period before surface mount printing, in2℃~8℃Store in the refrigerator.3~6The soldering performance of the solder paste should remain unchanged for a month.

2The metal powder in the solder paste does not separate from the flux.

3It has low hygroscopicity,Low toxicity, odorless and non-corrosive.

Ii. When using solder paste

1It is required that the viscosity of the solder paste changes little over time. When printing continuously at room temperature, it is required that the solder paste does not dry easily, has good surface mount processing printability (rolling property), and a long working life.

2It has good demolding property and is suitable for continuous printing,Do not clog the leakage holes of the formwork.

3After printing, maintain the original shape and size without any collapse (collapse after cooling))It has good thixotropy (conformal property))

4Place it at room temperature after printing12~24h,At least4h,Its performance remains unchanged.

Iii. During reflow soldering

1During the preheating process of reflow soldering,It is required that the solder paste undergoes minimal deformation during the collapse process.

2During reflow soldering, it has good wettability, less solder spatter, and forms the smallest amount of solder balls.

3It has good wetting performance.

Four. After reflow soldering

1The weld points formed behind the furnace have sufficient strength to ensure that they will not fail due to factors such as power supply and vibration.

2The residue after welding has good stability, is non-corrosive, and has a relatively high insulation resistance. The solvent-cleaning type and water-cleaning type require easy cleaning after welding.

The above content is shared by Shenzhen JJY Solder Paste Manufacturer for you. We hope it will be helpful to you. If you want to know more about solder paste andSMTKnowledge of surface mount technology (SMT) processing. Welcome to leave a message and interact with us!

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account