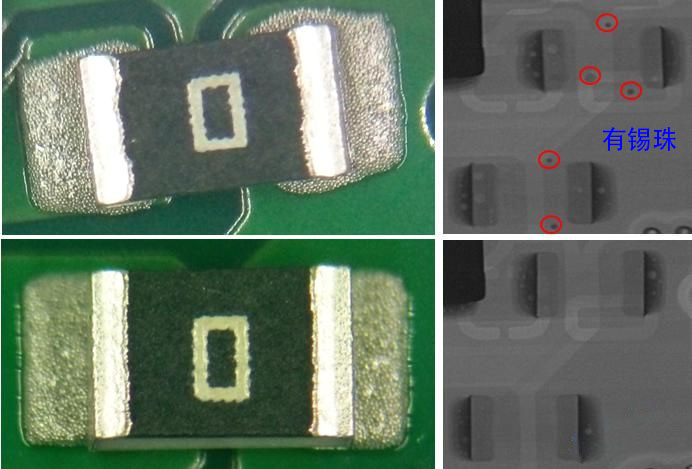

SMTSometimes, during the production and processing in a surface mount technology (SMT) processing factory, the phenomenon of tin explosion occurs, which means soldering points are formed during the processingSolder pasteExplosion occurs, resulting in incomplete solder joints, pores, solder beads and other phenomena. Below, Shenzhen JJY Solder Paste Manufacturer will briefly introduce to you the common reasons for the occurrence of solder cracking:

The reason for the occurrence of tin frying is usually due toPCBCaused by moisture and in a high-temperature state during the welding processPCBTin explosion often occurs after coming into contact with solder. To solve this problemSMTA surface mount technology (SMT) processing factory can be located atPCBDuring the storage process, vacuum packaging is used or baking is carried out before the start of production and processing.PCBThe time for baking components on the board needs to be set according to the actual situation.

Apart from moisture, the incorrect use of flux is also one of the reasons for the occurrence of solder soldering. This includes excessive use of flux, moisture absorption of flux, and abnormal composition ratios, all of which can lead to itSMTPoor processing occurred in the surface mount technology (SMT) processing. To avoid these processing defects caused by improper use of flux, some points also need to be noted, such as sealed storage of solder paste, selection of solder paste with appropriate flux, and strict control of flux composition, etc.

As a 15-year-old veteran solder paste manufacturer, JJY has been committed to the research and development, production and sales of solder paste. The quality of the solder paste is stable, without solder bonding, false soldering or establishing a reputation. No residue, Wuxi beads, bright, full, firm solder joints with excellent electrical conductivity. If you have any needs, please feel free to contact us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account