insmtDuring processing, many customers usually have requirements for the glossiness of reflow solder joints. The quality of solder joints directly affects the service life and reliability of electronic products. However, during the reflow soldering process, it cannot be guaranteed that the glossiness of each reflow solder joint meets the requirements. So, what are the reasons for the insufficient glossiness of reflow solder joints?Now, Shenzhen JJY Solder Paste Manufacturer will take you to learn about it:

The main factors affecting the glossiness of reflow solder joints

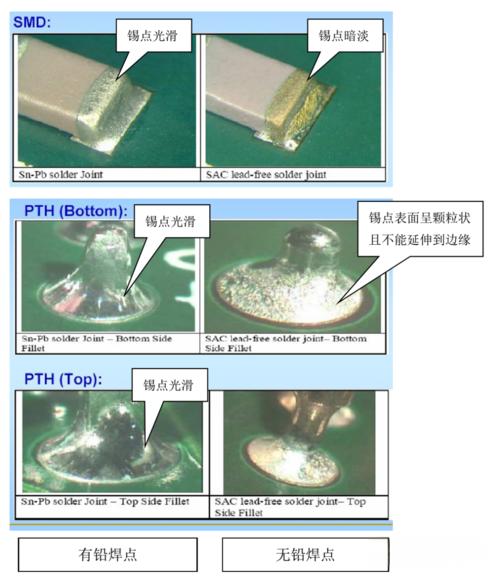

1The composition of solder paste is different, which will affect the gloss of the solder joints. For example, the solder joints presented are different when the solder paste contains silver and when it does not.

2Whether the tin powder in the solder paste is oxidized or not will cause differences in the gloss of the solder joints.

3Whether there are any additives in the flux itself in the solder paste that form a matting effect;

4During the reflow soldering process, if the reflow soldering temperature is insufficient or too high, causing the flux to evaporate prematurely, it will directly affect the gloss of the solder joint.

5In reflow soldering, the preheating temperature of reflow soldering is relatively low, and there may be substances that are difficult to evaporate remaining on the surface of the solder pad, which will affect the gloss of the reflow solder joint

6After reflow soldering, whether there is rosin or other impurities remaining on the surface of the solder joint is a common phenomenon, which will affect the gloss of the solder joint.

JJY16We have been dedicated to the research and development, production and sales of solder for many years, providing customers with a complete set of electronic soldering solutions. Want to know moreSolder pasteFor more information on this aspect, please keep following JJY Solder Paste Manufacturer and leave a message online to interact with us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account