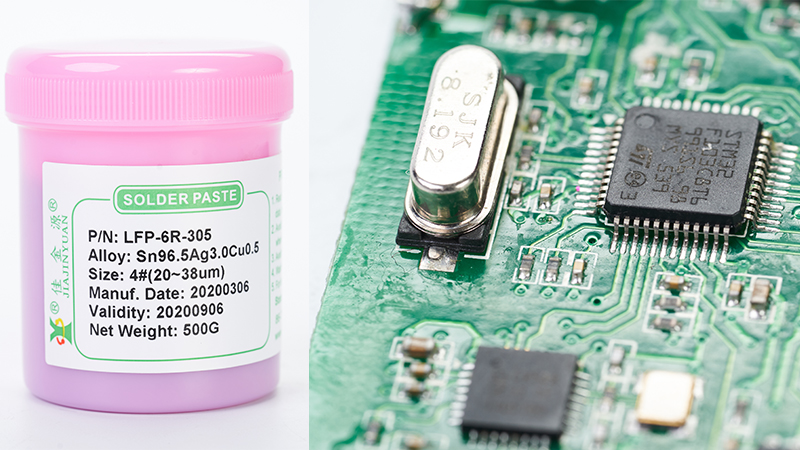

SMTDuring processing, tinning is an important processing step in surface mount soldering, and it will directly affectSMTThe quality of surface mount technology (SMT) soldering can be said to be the core quality of SMT processing. The occurrence of tin coating defects is not a rare thing. However, if these defects are not dealt with in time, they will cause some troubles in processing. So, what are the causes of tin coating defects? The following ShenzhenSolder paste manufacturerLet me give you a brief introduction:

1If the amount of solder paste at the solder joint is insufficient, it is very likely to cause the soldering to be not smooth and have notches.

2Excessive flux expansion rate can also easily lead to defects such as cracks at the solder joints.

3The wetting performance of the flux is not good;

4Solder pads orSMDOxidation occurs at the welding position;

5The activity of the flux is insufficient to achieve the removal of solder pads and componentsSMDSurface oxides at the same position

6InSMTIf the solder paste is not thoroughly stirred evenly before processing, it will also lead to the inability of the flux and solder powder to combine fully, resulting in the phenomenon that the solder on the solder joint is not smooth.

7When passing through the reflow soldering oven, if the heating time is too long or the heating temperature is too high, it will result in the ineffectiveness of the flux activity in the solder paste.

Shenzhen JJY Industrial Technology Co., Ltd. is a company15As a manufacturer specializing in the research and development and customization of solder paste, lead-free solder paste and leaded solder paste for many years, if you want to learn more about solder paste, please continue to follow JJY Solder Paste Factory and leave a message online to interact with us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account