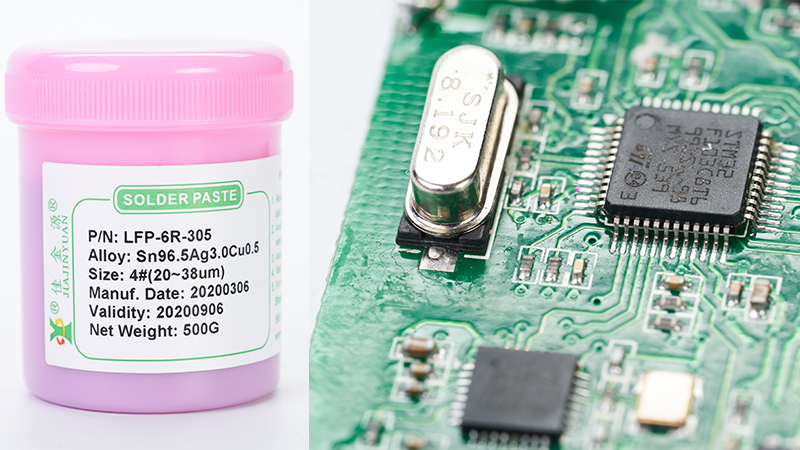

Welding technologySMTThe core technology, so we need to select and prepare in line with itSMTRequiredSolder pasteIt is of vital importance.SMTSpecial solder paste is a mixture composed of tin-based alloy powder and flux paste. In the currently commonly used no-clean and water-clean solder pastes, the content of tin-based alloy powder reaches80wt%-91wt%From this, it can be seen that the quality of tin-based alloy powder is closely related to the quality of solder paste.

inSMTDuring the application of special solder paste, from the printing of solder paste,SMDFrom surface mount to reflow soldering, we often encounter various problems, which frequently trouble the users of solder paste. How to analyze and solve these problems has also become a topic for solder paste manufacturers;Therefore, it is very necessary for solder paste manufacturers to constantly enhance the professional quality and business level of their marketing personnel. After the products are delivered to users, assisting users in properly and promptly handling these issues can also reflect the service intensity of the suppliers.

SMTSpecialized solder paste needs to meet technical requirements such as bright solder joints, excellent wettability, good solderability, few bridging, few solder beads, and few voids. Correspondingly, tin-based alloy solder powder should have the characteristics of low impurity content, low oxygen content, uniform particle size, and spherical morphology. Below, the solder paste manufacturer will explain the reasons for the incomplete solder coating on the solder joints:

1,PCBSolder pad orSMDThere is a serious oxidation phenomenon at the welding position.

2The activity of the flux in the solder paste is insufficient.PCBSolder pad orSMDThe oxides at the welding position cannot be completely removed.

3The temperature in the reflow soldering area is too low;

4The wetting performance of the flux in the solder paste is not good;

5If there are some solder joints where the solder is not fully coated, it might be that the solder paste was not thoroughly stirred before use, and the flux and solder powder were not fully mixed;

6The amount of solder paste at the solder joint is insufficient;

7During reflow soldering, if the preheating time is too long or the preheating temperature is too high, it will cause the flux activity in the solder paste to fail;

Shenzhen JJY Industrial Technology Co., Ltd. is a company15As a manufacturer specializing in the research and development and customization of solder paste, lead-free solder paste and leaded solder paste for many years, if you want to learn more about solder paste, please continue to follow JJY Solder Paste Factory and leave a message online to interact with us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account