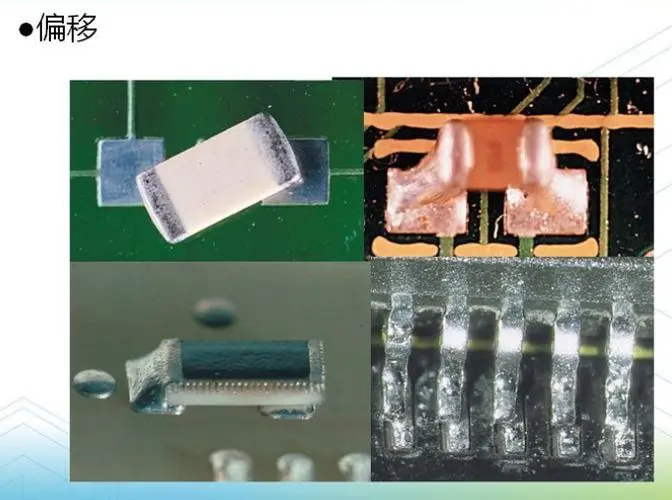

What issmtDisplacement of surface mount processing components? inSMTThis is actually an undesirable phenomenon during the processing in the factory. With the development of technology and the improvement of people's living standards, the pursuit of electronic products is increasingly moving towards miniaturization and precision. Traditional in general processing plantsDIPThe plug-in is small and compactPCBAThe role it plays is no longer as significant as beforeSMTSurface mount technology (SMT) processing, especially large-scale and highly integrated onesIC. But inSMTSome problems may also occur in surface mount technology (SMT) processing, such as component displacement. Now, JJY solder Paste Manufacturer will introduce professionalism to yousmtWhat causes the displacement of components in surface mount technology (SMT) processing?

1The usage time of solder paste is limited. Exceed itSMTAfter the service life of the solder paste, the flux in it deteriorates, which leads toPCBAPoor surface mount soldering.

2The solder paste itself is not sticky enough, and problems such as oscillation and shaking occur during the transportation of the components, causing the components to shift.

3The flux content in the solder paste is too high. During the reflow soldering process, the excessive flow of flux causes the components to shift.

4The components areSMTPrintingPCBADuring the handling process after surface mount technology (SMT), the components shifted due to vibration or incorrect handling methods.

5During the surface mount technology (SMT) processing, the air pressure of the suction nozzle was not adjusted properly, resulting in insufficient pressure and causing the components to shift.

6The mechanical problem of the surface mount technology (SMT) machine itself caused the incorrect placement of components.

Shenzhen JJY Technology Industrial Technology Co., Ltd. is a professional solder paste manufacturer,15We have been dedicated to the research and development and production of solder paste for many years,We offer wholesale and direct supply of solder paste of different models. For more details, please feel free to consult us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account