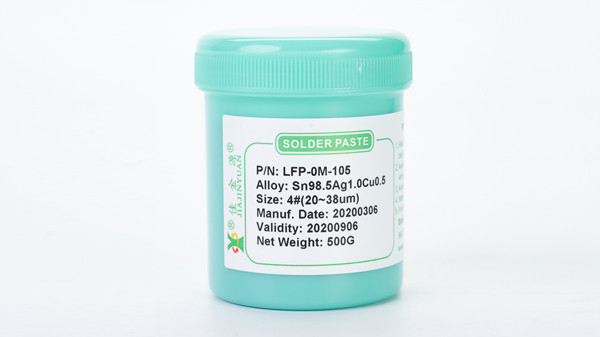

How to stir correctlyLead-free solder paste? In this era of information development, everyone has several electronic products. To produce these electronic products, solder paste is indispensable. As we all know, lead-free solder paste is a substance with very active chemical properties, so it has very strict requirements for the environment. So, how do people generally use lead-free solder paste? Since it needs to be warmed up and thoroughly stirred before use, the solder paste manufacturer will introduce it to you below:

In fact, the stirring of solder paste is to obtain the appropriate printing viscosity.

We know that due to its certain thixotropy, the actual viscosity of solder paste during the printing process is different from that in its static state. The best printing effect of solder paste is achieved within a certain range of viscosities.

If the solder paste is printed directly without stirring, its viscosity will be too high. The first piece or the first few pieces will have a series of problems such as poor tin discharge, lack of rolling property, and sticking to the scraper.

The next issue is how to determine the stirring time, which is related to the formula of each solder paste itself.

Solder paste is generally stored in a refrigerator, and the freezing temperature is at5-10The degree is excellent. Therefore, when taking solder paste out of the refrigerator, its temperature is much lower than the room temperature. If the bottle cap is opened without rewarming, it is very easy for the water vapor in the air to solidify and adhere to the solder paste. When passing through the reflow oven, the water will rapidly vaporize due to the strong heat, causing a tin explosion, resulting in solder beads and even damaging electronic components. Solder paste warming method: Place it at room temperature without opening the bottle cap to thaw naturally. Warming time:4For about an hour, good solder paste will maintain a stable viscosity during the printing process. Such solder paste will not have a significant impact on viscosity even if it is stirred for a long time. However, during the stirring process, the solder paste will heat up, thereby affecting the service life of the solder paste.

For some solder pastes, their viscosity will gradually decrease during the printing process. Besides the aforementioned effects, excessive stirring time may cause the viscosity of the solder paste to drop, thereby affecting its usability.

Some solder pastes have a higher viscosity during the printing process. This is because the solvents in them evaporate too quickly. If the solder paste is stirred for too long, it will only affect its service life.

Want to know about solder pasteLead-free solder pasteFor any soldering issues such as solder paste, we welcome partners to consult Shenzhen JJY Industrial Technology Co., LTD. Let's learn and grow together! The solder wire, solder paste and solder rods of JJY brand are always waiting for partners to come and take them together.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account