Previously, we mentioned that solder paste may have solder whiskers growing after soldering. Whiskers are conductive metal wires that grow spontaneously on the pads of electronics or electronic products. For example: terminals of electronic devices, metal shielding shells, etc. Metals that are particularly easy to produce whiskers mainly include tin, cadmium, zinc, etc. The most representative one is tin whiskers. Xpeng Motors once recalled over ten thousand vehicles because tin whiskers produced by inverters could easily cause short circuits. Today Solder paste manufacturerLearn about the causes and treatment methods of tin whiskers:

I. Properties and Reasons of Tin Whiskers

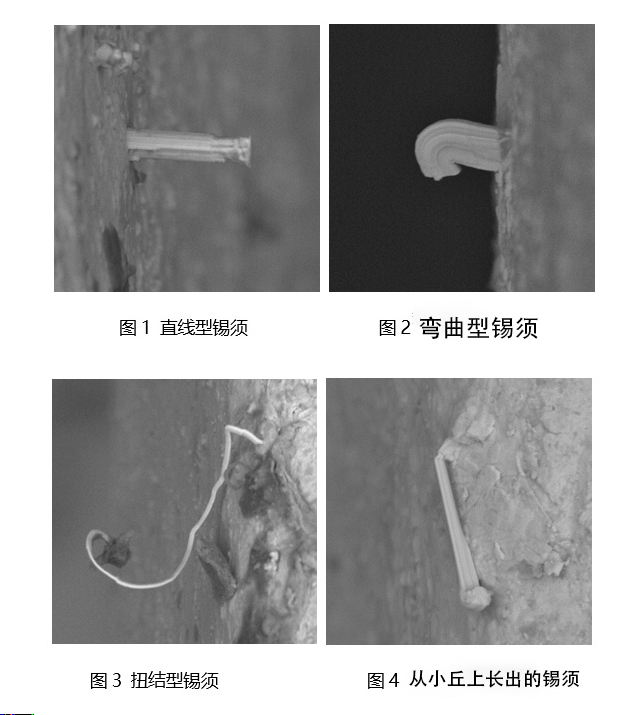

Tin whiskers are surface defects that spontaneously form on pure tin or objects with high tin content. The cause of tin whiskers has not yet been determined in the industry, but it is generally believed that it is caused by the stress of the inner layer of tin. The most common research holds that the growth of tin whiskers begins on the pure tin electroplating layer. Once the growth process gradually starts, the tin whiskers gradually begin to grow from the "lower part", and the material supply is provided by the diffusion of tin atoms in a larger area. Therefore, there is no reduction in layer thickness at the root of the tin whiskers. Sometimes the direction of growth may change all at once, thus causing the bending of the tin whiskers.

Ii. Hazards of Tin Whiskers

1Residue pollution

Considering that mechanical shock or vibration can cause tin whiskers to fall off the surface of the coating, generating debris. If these residual conductive material particles operate at will, they may interfere with sensitive human optical signals or the operation of micro-electromechanical systems. In addition, the residues may also cause short circuits.

2Transient short circuit

When the short-circuit current composed of tin whiskers has exceeded the current it can withstand (mostly)30mAAt this time, the tin whiskers will be melted, generating intermittent short-circuit pulses. In such cases, it is mostly difficult to detect.

3Permanent short circuit

When the tin whiskers grow to a certain length, two different conductors can be short-circuited. The current in a low-voltage, high-impedance circuit is not sufficient to melt and open the tin whiskers, resulting in a permanent short circuit. When the diameter of the tin whiskers is large, a higher current can be transmitted.

4Metal vapor arc in a vacuum

Under vacuum (or low pressure) conditions, if the tin needs to transmit a relatively large current (several amperes) or a relatively large voltage (approximately18(V), tin whiskers will evaporate into ions and be able to transmit several hundred amperes of current. The maintenance of the current arc relies on the tin on the surface of the coating until it is exhausted or the current stops. Such incidents are very likely to occur within devices like fuses or when circuits are disconnected. There was once a commercial satellite that caused this situation, leading the satellite to deviate from its orbit.

Iii. Specific Measures for the Prevention and Inhibition of Tin Whiskers

Given that the appearance of tin whiskers takes a long time and may cause serious harm after their occurrence, it is necessary to start with the prevention and inhibition of tin whiskers growth in order to solve the tin whiskers problem. So far, the generally effective methods are not very clear, but generally, it is to avoid the generation of compressive stress inside the solder coating as much as possible.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account