Everyone who has used solder paste is quite clear that there are two types of this product: halogen-free and halogenated. With the rapid development of The Times, halogen-free products used in many industries will become an inevitable choice. So, do you have a good understanding of this? Below, the solder paste manufacturer will explain the detailed description of this product to you

Product Introduction:

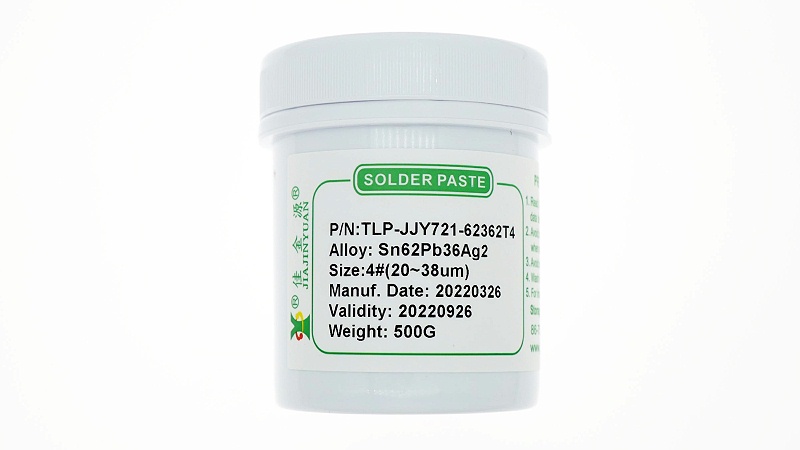

1This oneThere is lead solder pasteIt is made with a scientific formula and spherical solder powder with low oxidation degree, and at the same time, the paste is refined with imported chemical materials, which can achieve very high stability and effect.

It has good demolding performance during printing, excellent dry resistance and good thixotropic performance, and can be applied to0.4mmPrinting of fine-pitch pads and fine-pitchQFN,BGAThe mounting of devices.

2Halogen-free0Halogen formula paste, with less residue after welding, low corrosiveness, and extremely high surface insulation resistance value, no need Cleaning can achieve excellent resultsICTTest performance.

3When printing continuously, the viscosity change is small, which can ensure the stability of the printing effect during long-term operation.

4This product has excellent thixotropic performance and maintains a good shape after printing,It is not easy to collapse and avoids the displacement of surface mount components.

5The weld points are bright after welding and have excellent electrical conductivity.

6Fewer solder beads are produced during welding, reducing the occurrence of short circuits.

The above is the product introduction of halogen-free solder paste for everyone. You can take a look. Later, we will explain the use of solder paste and some subsequent preparations. If you are interested, welcome to consult.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account