Recently, many people have been saying that circuit board manufacturers complain that the cost of using the entire solder paste is too high. As a legitimate companySMTManufacturers, they all expect to effectively reduce the overall costSMTThe production cost required for the welding process. In useLead-free solder pasteWhen it comes to the manufacturer's products, it is obvious that a small bottle of solder paste may seem insignificant, but the price of solder paste is extremely high. A bottle costs several hundred yuan, but something that looks expensive is extremely outrageous. Although as a legitimate lead-free solder paste manufacturer, when choosing a solder product, we all expect enterprise customers to meet market demands at the lowest production cost, however, under the unique national conditions of our country, affordability also means that there is no such thing as product quality.SMTFor manufacturers to effectively reduce the operating costs of lead-free solder paste, they need to take into account multiple factors to make a choice. The following is an explanation from the solder paste manufacturer:

To effectively reduce the operating cost of solder paste, one can directly start from these aspects:

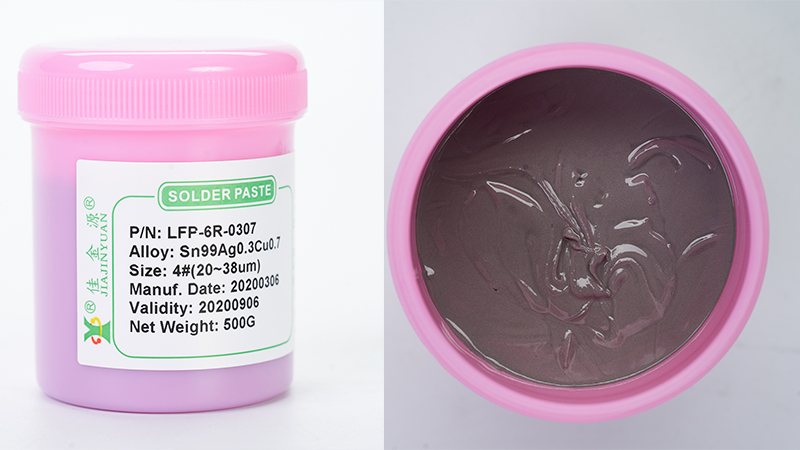

1Choose the correct solder paste product

Even though the price of solder paste is not the higher the better, the reason for its high cost is that it is related to circuit board factoriesSMTIn contrast, choosing cost-effective solder paste can be a difficult issue. When making a decision, do not deliberately pursue the lowest price of lead-free solder paste. The purpose of solder paste is to promote the requirements of the soldering process. Only when it does not affect the requirements of the soldering process will the production cost and market demand be taken into account. Solder paste is a kind of product that meets the requirements of the soldering process. The manufacturers constantly process and manufacture, and the processing also needs to cooperate with the suppliers. The reasonable selection of solder paste products requires careful consideration: Welding process requirements, production cost requirements and customer satisfaction of lead-free solder paste manufacturers.

2Greatly reduce the dosage

As long as solder paste is in use, there will definitely be more or less waste, becausesmtIt is also inevitable for manufacturers to implement soldering process requirements. Our opinion today is that the utilization of surface mount technology (SMT) machines should mainly focus on minimizing unnecessary waste. By simplifying the specific steps of the soldering process requirements and upgrading the SMT process, the lead-free solder paste wasted during the printing process can be collected and appropriately utilized, which will effectively reduce operating costs to a large extent. By upgrading the soldering process to achieve high precision in controlling the position of the solder joints, omissions can be greatly reduced, which will significantly decrease the amount of solder paste used.

3Alternate the old and the new

It is an undeniable fact that the latest type of solder paste is better than the requirements of the soldering process. This is mainly due to the production and processing technology of lead-free solder paste manufacturers. The flux and other components inside lead-free solder paste will undergo trace chemical reactions during long-term storage. This is why solder paste begins to be transported from the manufacturing manufacturers tosmtAn important reason why producers need to store at low temperatures. The flux components inside new solder paste and old solder paste are due to chemical reactions and have some differences. Within the permitted range, it is recommended that surface mount technology (SMT) manufacturers do not blindly discard old solder paste. Instead, they can alternate between new and old ones for use, which can significantly and effectively reduce the operating cost of solder paste.

veryWhen multiple brands are choosing solder paste products, they all expect to select a manufacturer with reliable product quality. Therefore, they will choose some manufacturers for analysis. They are quite fond of learning about the top ten rankings and even the market prices for selection. Such choices by enterprise customers are quite normal.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account