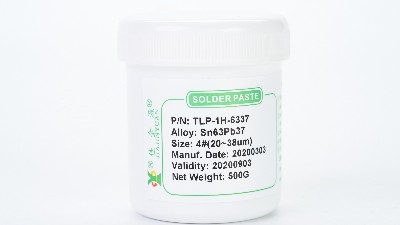

There is lead solder paste6337The series is specifically designed forSMTThe no-clean solder paste designed by the process is made by using special solder paste and oxide spherical solder powder. This product is of high quality, easy to use, has a wide range of applications and excellent continuous printing performance. Solder pastes with different alloy compositions, different tin powder particles and different metal contents can be provided. Meet the technological requirements of different products.

The applied printing window is wide, and special soldering flux technology is employed to continuously improve the process performance, greatly reducing the soldering defects after reflow soldering. It has strong activity and is very suitable for products with oxidation problems. The welding is lustrous and it has strong climbing ability. It has strong activity, good moisture retention, good printing rolling property, good tin reduction property, and the spacing can be reduced to0.3mmThe pad printing is exquisite, the viscosity change is small during continuous printing, and it has a long operational service life on steel screens.8It can still have a good printing effect after more than a few hours.

Take into account6337Solder paste is a paste-like product and is prone to losing moisture. If the working temperature is too long, the solder paste is prone to drying out;The recovery time of the working temperature is relatively short, and tin beads are prone to form during the operation process. In that case,6337How should we warm up the solder paste to ensure its continued use?

Before using solder paste normally, considering that the storage working temperature of solder paste is relatively low, it must be stored at2-10℃. So, most solder paste manufacturers store them in freezers, but the solder paste needs to be brought back to room temperature during continued use. Otherwise, the solder paste will be in a very bad condition. Therefore, the solder paste should be thawed before normal use.

6337Thawing time of solder pasteSMTIndustry standard4Hours. A lot of domestic solder paste is necessary3Hours. Import demands are more stringent. It must be just the right time. This is because different solder pastes from different solder paste manufacturers have different storage conditions at room temperature. Many solder pastes can be stored for several months without any problem, so most of them dry after being stored for just a few days or even a few hours. Therefore, the thawing time is generally around four hours.

When the climate temperature rises, corresponding changes should be made. According to the demands of different solder paste manufacturers, if6337The solder paste needs to be preheated at room temperature4During the hours, it is usually in summer3About an hour. Of course, it depends on the actual situation. If some solder paste can be preheated3If it takes an hour, it's all over. We definitely need to keep warming up. Besides, it can't be warmed for too long. If it is too long, the high temperature in summer will cause the solder paste to dry out easily.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account