Solder pastePrinting is for doing wellPCBAIt is of vital importance. It has a direct impactPCBAThe overall welding effect. inPCBADuring the processing, how to do a good job in solder paste printing has become a problem that production managers must consider. The effect of solder paste printing is composed of four parts: steel mesh, solder paste, printing process and detection method. Now, let's take a look together with Shenzhen JJY Solder Paste Manufacturer

1. Steel mesh

The issuance of steel mesh must be based on certain groundsPCBAThe layout of electronic components on the board should be appropriately enlarged or reduced to determine the amount of solder paste on the pads, thereby achieving the best soldering effect. To prevent phenomena such as continuous tin and insufficient tin, strict evaluations by process engineers are required. In addition, the material of the steel mesh is also quite crucial, as it affects the tension of the steel mesh and its service life after repeated use, etc.

In addition, the cleaning and storage environment of the steel mesh before feeding is particularly crucial. Before each online operation, a strict cleaning must be carried out, and it is necessary to check whether the through holes are blocked or have tin slag, etc. PartPCBAThe manufacturer suggests purchasing a steel mesh tensiometer and conducting a tension test on the steel mesh before each feeding.

Ii. Solder paste

Solder paste should be selected from medium to high-end brands, and it is even better if it contains active ingredients such as gold or silver. Solder paste must be stored strictly2to10In the refrigerator of the degree, relevant statistics must be made for each entry and exit. The recycling of solder paste must be strictly controlledIPCWithin the standard range and strictly follow the solder paste stirring procedure before going online.

Iii. Solder paste Printing

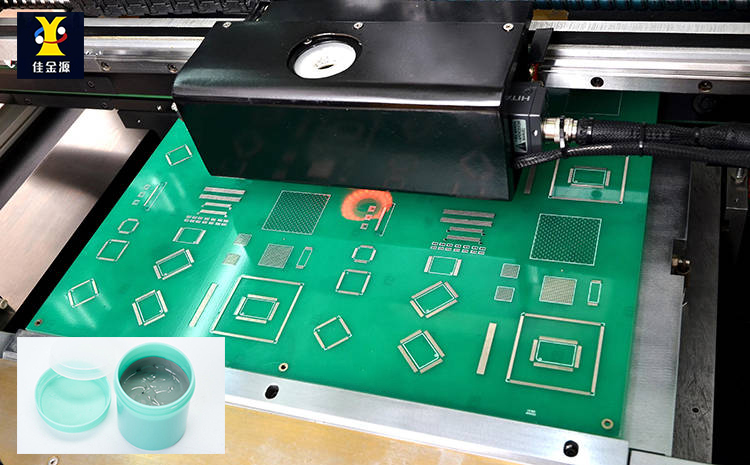

At present, many manufacturers are using fully automatic solder paste printers. Its equipment can well control parameters such as the force and speed of printing, and has a certain automatic cleaning function. The operator only needs to set the parameters strictly in accordance with the regulations.

During the mass production process, the detection of phenomena such as hole blockage and misalignment of steel mesh is particularly important, especially after printingSPIWhen some of the detected defects show an upward trend, the machine must be shut down to check the operating condition of the steel mesh itself.

Iv.SPIPrinting effect detection

After the solder paste printer, configureSPIThe solder paste detector is particularly important. It can effectively detect numerous defects in the solder paste printing process, such as insufficient solder, continuous solder, notches, wire drawing, and misalignment. So as to maximize the overall weldingPPMValue.

Shenzhen JJY owns16With years of experience in research and development and production, we have a strong technical force and stable product quality. Flagship products:QFNHigh solder climbing rate solder paste, zero halogen solder pasteVOIDLow-porosity solder paste, laser solder paste, water-washed solder paste, and high-reliability ones used in military, aerospace, power, photovoltaic and other industriesSn62Pb36Ag2Solder pasteSn62.8Pb36.8Ag0.4Solder paste6337Solder paste, transparent and colorlessLEDHigh-brightness anti-monument solder pastemini-LED/micro-LEDDie bonding solder paste, high-reliability lead-free low-temperature solder paste, low-temperature solder paste for heat sinks, lead-free medium-temperature solder paste, lead-free high-temperature0307/105/305Solder paste, etc. Proprietary technology, strict quality control, continuous stability, making customers worry-free, efficient, cost-effective and competitive!

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account