inSMTIn surface mount technology (SMT) processing, the quality of component placement is of Paramount importance, as it directly affects the stability of product usage. What factors exactly can affect the quality of surface mount technology? Next, Shenzhen JJYSolder paste manufacturerLet's explore it together:

First of all, the accuracy of the components is crucial. During the surface mount technology (SMT) process, each component at the assembly position number must strictly follow the requirements of the product's assembly drawing and detail list. There must be no mistakes in terms of type, model, nominal value or polarity. If the components are pasted in the wrong position, it will directly affect the performance and stability of the entire product.

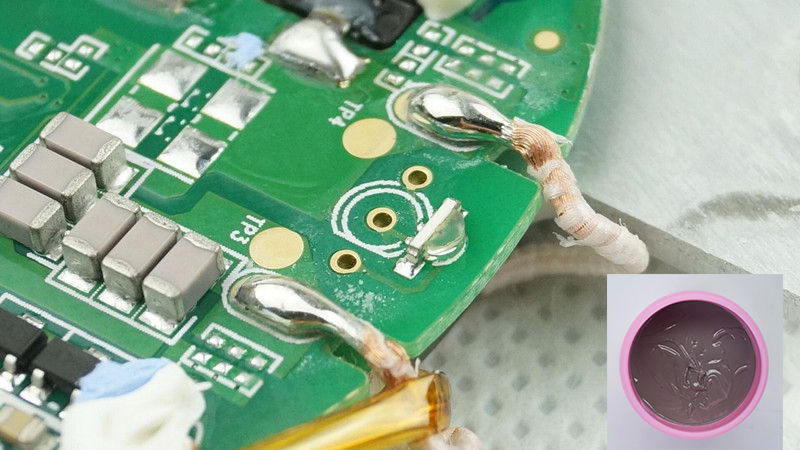

Secondly, the accuracy of the mounting position should not be ignored either. The ends or pins of the components should be aligned and centered as much as possible with the solder pad pattern to ensure accurate contact between the solder ends of the components and the solder paste pattern. In addition, the placement positions of components must also meet the process requirements to ensure the soldering effect and the stability of the product.

Furthermore, the control of the patch pressure (i.e., the height of the patch) is also of vital importance. The pressure of the patch is equivalent to that of the suction nozzleZShaft height. This height must be moderate. If the surface mount pressure is too small, the solder ends or pins of the components may float on the surface of the solder paste, causing the solder paste to fail to adhere firmly to the components. As a result, positional shifts occur during the transfer and reflow soldering processes. On the other hand, ifZIf the shaft height is too high, when components fall from a height, the surface mount position may shift. Excessive surface mount pressure may cause an excessive amount of solder paste to be extruded, leading to solder paste adhesion and bridging. At the same time, it may also cause the surface mount position to shift due to sliding, and in severe cases, even damage the components.

To sum up, inSMTIn surface mount technology (SMT) processing, ensuring the correctness of components, precise positioning, and moderate placement pressure is the key to guaranteeing the quality of component mounting. Only by strictly controlling these factors can the stability and reliability of the product be ensured.

JJY solder Paste Manufacturer mainly engages in lead-free solder paste.SMTSurface mount solder pasteLEDResearch, development, production and supply of solder pastes, lead-free solder wires, wave soldering rods and other solder solders. For more knowledge about electronic soldering, please contact us. Welcome to interact with us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account