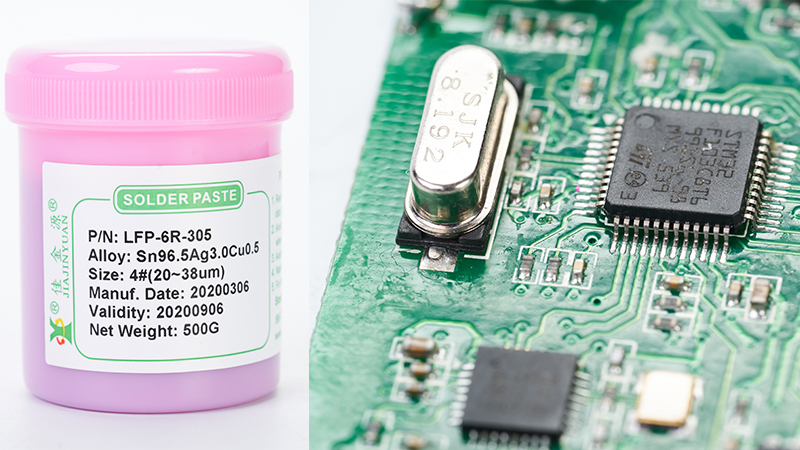

Circuit boardSolder pasteAfter reflow soldering, sometimes bubbling occurs. What causes this? The fundamental reason lies in the presence of gas or water vapor between the base material and the solder mask film. Trace amounts of gas or water vapor can be carried in along with different technological processes. When exposed to high temperatures, gas expansion causes the base material to delaminate from the solder mask film. During welding, due to the high temperature of the solder pad, bubbles usually appear around the solder pad first. Next, JJY solder Paste Manufacturer will discuss the reasons and solutions together:

The reasons for the green oil bubbling on the circuit board:

1When there is gas or water vapor between the solder mask and the substrate, a small amount of gas or water vapor will be carried in different process procedures. When exposed to high temperatures, gas expansion can cause the solder mask film to separate from the anode substrate. During welding, due to the high temperature around the pad, bubbles first appear around the pad.

2During the processing, cleaning and drying are usually required before proceeding to the next procedure. Generally, after etching, the solder mask must be dried before it adheres. If the drying temperature is insufficient, water vapor may be carried to the next process.

3Before the circuit board was processed, the environmental storage conditions were poor, with excessive humidity, and it was not dried in time during soldering. In solder paste reflow soldering, if the temperature is insufficient during the preheating of the circuit board, water vapor will enter the interior of the circuit board substrate through the through-hole walls, and the vapor will first enter the area around the solder pads. When welding is carried out at high temperatures, all these situations will lead to the formation of bubbles.

Solution for foaming circuit boards:

1Strict control is needed at every stage. The purchased circuit boards should be inspected before being stored in the warehouse. Under normal conditions, bubble problems usually do not occur.

2Circuit boards should be stored in a well-ventilated and dry environment, and the storage time should not exceed6One month.

3Before soldering, the circuit board should be placed in an oven for pre-baking, and the temperature should be controlled at105℃"Continuous"4to6Hours.

Shenzhen JJY Industrial Technology Co., Ltd. is a company16As a manufacturer specializing in the research and development and customization of solder paste, lead-free solder paste and leaded solder paste for many years, if you want to learn more about solder paste, please continue to follow JJY Solder Paste Factory and leave a message online to interact with us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account