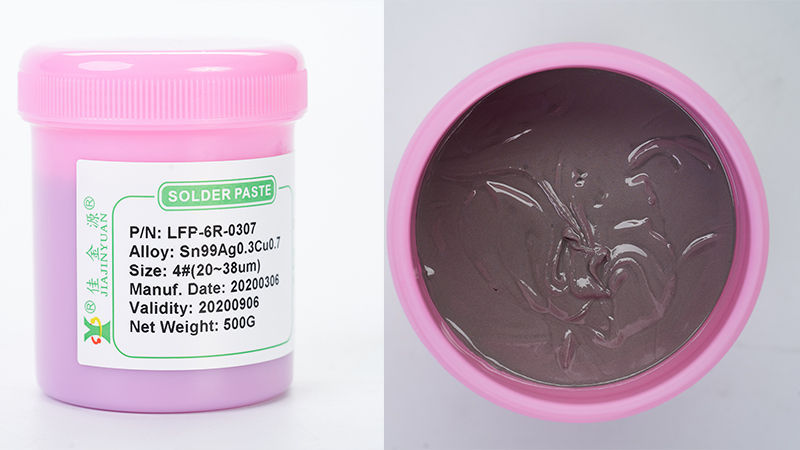

JJYLead-free solder paste without washing0307It is specially developed for fine-pitch printing, placement and reflow applications, and can be used in air or nitrogen environments, both of which can achieve highly reliable solder joints. The wide production technology window ensures its applicationOSPSilver immersion, tin immersionENIGAnd lead-freeHASLThe excellent soldering performance under surface treatment conditions is explained by the solder paste manufacturer below:

JJY lead-free and no-wash solder paste0307It mainly has the following characteristics and advantages:

The weld points are firm, bright and full

12With years of professional R&D experience, we have rationally and effectively mastered the components of modern social production technology, ensuring that the solder paste is highly compatible with the soldered products. The solder joints are firm, bright, uniform, full and free of solder beads.

Low residue, no need for cleaning

We have developed and formulated a no-wash and environmentally friendly flux. After welding, it leaves little residue, has high insulation resistance, the board surface is clean and free of corrosion, and forms a protective layer to prevent the substrate from oxidizing again.

It has strong wettability and good tin crawling

High-performance thixotropic agents are added to the solder, making the solder paste highly active. When the solder paste melts, the solder obviously wets the solder pad, greatly reducing the phenomenon of false soldering and false soldering in the soldering process.

The printing is stable and has good demolding properties

The tin powder particles have good roundness and uniform size. During printing, there is no trailing, sticking or splashing phenomenon. There is no collapse, sharp or continuous tin connection during molding. The viscosity change during continuous printing is small and it does not dry out. The components do not shift.

0307Lead-freeSolder pasteShould be5-10℃The storage period under the environment is6Months, not less than0℃Store under such conditions and thaw before use2-4It should be left to room temperature for more than an hour before opening to prevent the formation of tin beads due to moisture. Then stir well before use.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account