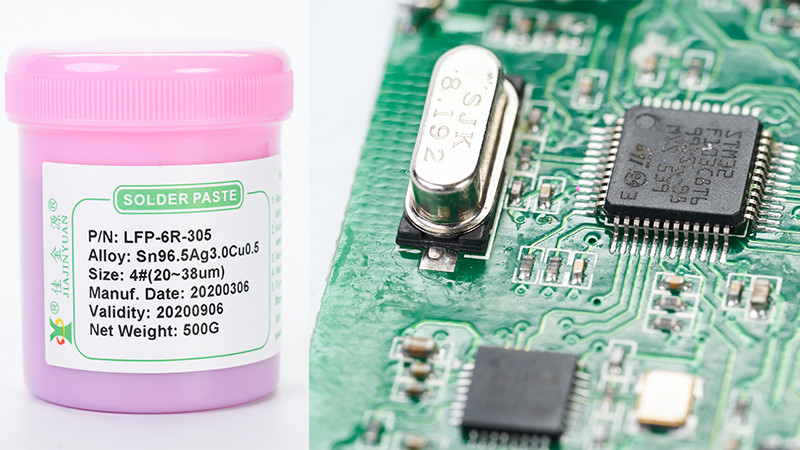

Welding is undoubtedlySMTIt is a very important processing step in factory surface mount technology (SMT) processing and also a processing step where processing defects occur frequently. Processing plants that prioritize quality will pay attention to welding quality, strictly control processing quality, and avoid the occurrence of processing defects. SoSMTWhat are the manifestations of poor soldering in surface mount technology (SMT) processing? Next, Jia JinyuanSolder paste manufacturerAnalyze and summarizeSMTCommon undesirable phenomena of patching, hoping to bring some help to everyone!

1There are holes on the surface of the solder joint: The main reason for this phenomenon is that the gap between the lead and the socket is too large.

2Asymmetric solder distribution: InPCBAThis phenomenon usually occurs becauseSMTIt is caused by the quality of the processed flux and solder, as well as insufficient heating.

3Insufficient solder: This is mainly caused by the premature removal of the solder wire. The strength of this defective solder joint is insufficient, and its electrical conductivity is weak. Under the action of external force, it is prone to cause the fault of component open circuit.

4The main reason for the sharp tip isSMTIt is caused by incorrect removal direction of the soldering iron during processing, or excessive temperature causing a large amount of flux to sublimate.

5White solder joints: This is usually caused by the soldering iron being heated too high or the heating time being too long.

6Pad peeling: The peeling phenomenon formed when pads are exposed to high temperatures, which can easily cause problems such as short circuits in components.

7Cold welding: The main manifestation of cold welding is that the surface of the solder joint appears like bean curd residue. The main reasons for this poor processing are insufficient temperature of the soldering iron or the shaking of the workpiece before the solder solidifies.

8There are cavities inside the solder joints: The main reasons are poor wetting of the leads or excessive gap between the leads and the sockets.

Shenzhen JJY Industrial Technology Co., Ltd. mainly engages in the production and operation of:SMTSolder paste manufacturers of solder paste, syringe solder paste, lead-free solder wire, wave soldering bar, automatic soldering wire, etc.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account