In the process of electronic processingSMTSurface mount technology (SMT) processing is a very important processing step, andSMTThe precision of surface mount technology (SMT) processing is also very high. Many poor phenomena in electronic processing are due toSMTIt was caused by some problems during the processing. Printing faults are common processing defects in the surface mount technology (SMT) processing. Therefore, most electronic processing factories will try to improve the quality of their SMT printing to solve and avoid printing faults. The following is a brief introduction of Shenzhen JJY Solder Paste Manufacturer:

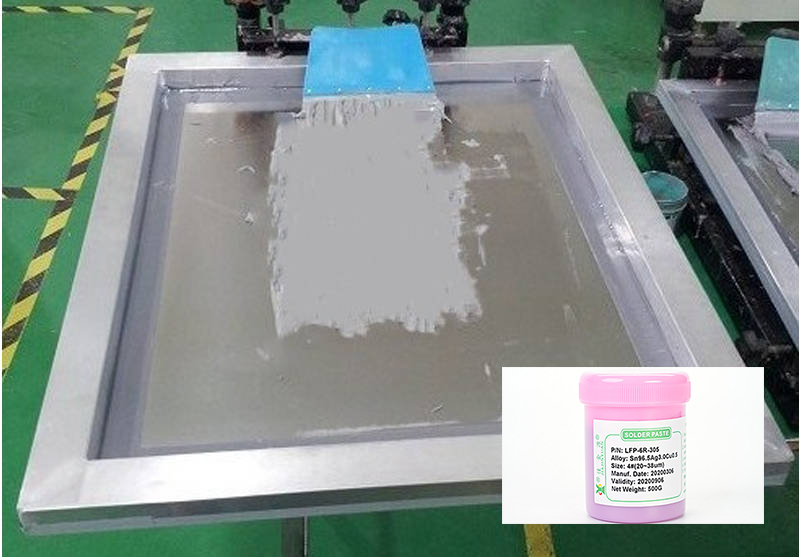

The printing method where there is no gap between the steel mesh and the circuit board is called "touch printing". It requires the stability of the entire structure and is suitable for high-precision printingSolder pasteThe steel mesh maintains a very flat contact with the circuit board and only separates from it after the printing is completed. Therefore, this method achieves a relatively high printing accuracy, especially suitable for solder paste printing with fine intervals and ultra-fine pitch.

1Printing speed

The solder paste will roll forward on the steel mesh under the push of the scraper. The fast printing speed of solder paste is beneficial to the rebound of the steel mesh, but at the same time it will hinder the desoldering of the solder paste. However, if the speed is too slow, the solder paste will not roll over the steel mesh, resulting in poor resolution of the solder paste printed on the pad. Generally, the printing speed range for fine intervals is10mm~20mm/s.

2Type of scraper:

There are two types of scrapers: plastic scrapers and steel scrapers. The spacing should not exceed0.5mmtheICWhen printing, a steel squeegee should be selected to facilitate the formation of solder paste after printing.

3Printing method:

NowSMTThe most common printing methods in processing are divided into "touch printing" and "non-touch printing". The printing method where there is a gap between the steel mesh and the circuit board is called "non-contact printing". The usual gap value is0.5mm~1.0mmSuitable for solder pastes of different viscosities.

4Adjustment of the scraper

The operating viewpoint of the scraper is as follows45°Printing in this direction can significantly improve the imbalance of solder paste in the opening directions of different steel meshes, and also reduce the damage to the openings of fine-spaced steel meshes. The pressure of the scraper is usually30N/mm².

As a 15-year-old veteran solder paste manufacturer, JJY has been committed to the research and development, production and sales of solder paste. The quality of the solder paste is stable, without solder bonding, false soldering or establishing a reputation. Residual Wuxi beads, bright and full solder joints, firm welding, and excellent electrical conductivity. If you have any needs, please feel free to contact us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account