SMTIn the solder paste processing factorySolder pasteThere are a great many types and specifications, even from the same brandSMTThe solder paste used by surface mount technology (SMT) processing plants in SMT processing also varies in terms of alloy composition, particle size, viscosity, cleaning methods, etc., and the price differences are also significant. Then how should one choose the appropriate oneSMTWhere is the surface mount solder paste?

Generally, the selection should be made in combination with the specific production environment, referring to the activity, viscosity, powder shape, particle size and melting point of the solder paste for surface mount processing.

1"Confirm"SMTThe ratio of alloy components in the solder paste to the flux paste in the surface mount. It directly affects the viscosity and printability of the solder paste.

2Reasonable selectionSMTSolder paste in surface mount solder paste. The printability and printability of solder paste mainly depend on the solder paste in the solder paste. Therefore, after determining the alloy composition in the solder paste, a solder paste that is suitable for the production process should be selected. When selecting, the activity of the printed circuit board and components should be chosen based on their storage time and the degree of surface oxidation: generally, this method is adopted for most productsRMAType High-reliability product selectionRType Printed circuit boards and components that have been stored for a long time and have severely oxidized surfaces are adoptedRAIt should be of the type and cleaned after welding.

3According to the process of applying solder paste andSMTSelect the viscosity of the solder paste for the density of surface mount assembly. There are various ways to apply solder paste, and different application methods have different requirements for the viscosity of the solder paste.

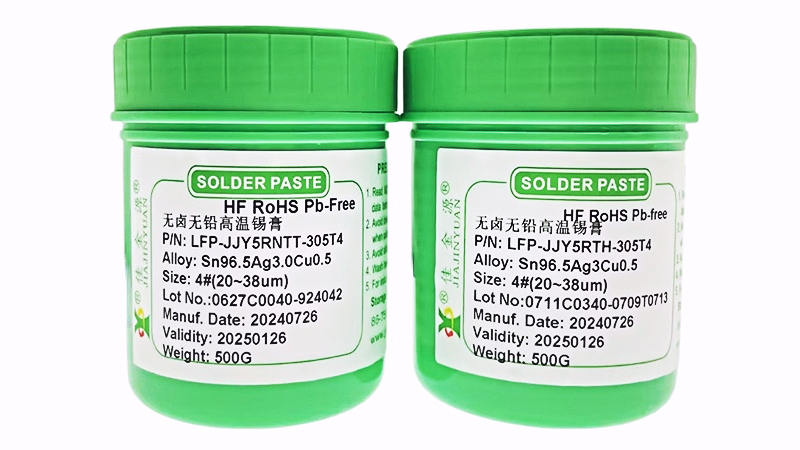

4,SMTWhen selecting solder paste in surface mount technology (SMT) processing, the alloy composition should be determined first. Alloy is the material that forms solder, and it forms an alloy layer at the interface with the metal to be welded. Meanwhile, the alloy composition also determines the welding temperature. Therefore, the alloy composition should be determined first. The alloy composition is mainly selected based on the electronic product and process. It is advisable to choose an alloy composition that is compatible with the component soldering as much as possible. At the same time, process factors such as soldering temperature should also be taken into consideration.

As a 16-year-old veteran solder paste manufacturer, JJY has been committed to the research and development, production and sales of solder paste. Our product quality is stable, with no solder connection, no false soldering, and no monument erection. Residual Wuxi beads, bright and full solder joints, firm welding, and excellent electrical conductivity. If you have any needs, please feel free to contact us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account