The metal components of lead-free solder paste include: tin, silver, copper, bismuth and other metals. Then, the one containing silverLead-free solder pasteWhat are the similarities and differences with lead-free solder paste containing copper? The common points of silver-containing solder paste and copper-containing solder paste: Both are lead-free solder paste series products and have passed the European UnionROHSCertified, it has the inherent characteristics of lead-free solder paste. Now, the solder paste manufacturer will provide a detailed explanation and analysis for everyone:

The main differences between lead-free solder paste containing silver and lead-free solder paste containing copper are as follows:

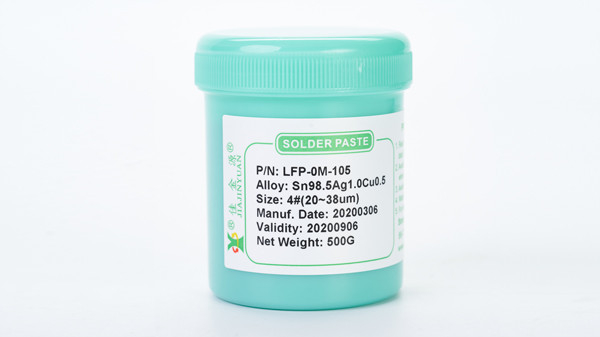

First, the metal compositions are different:Silver-containing lead-free solder paste is composed of tin-silver-copper or tin-bismuth-silver alloys, while tin-copper lead-free solder paste is made up of tin and copper alloys and does not contain silver metal components.

Second, different melting points: Due to the differences in metal alloys, their melting points also vary. containing3.0The melting point of silver solder paste is:217The melting point of lead-free tin-copper solder paste is:227Degree. Difference10Degree.

Iii. Different luster colors of solder joints: The luster color of solder joints affects the brightness and color of their appearance. Since silver metal is a matte metal rather than a bright one, the solder joints of silver-containing solder paste do not have a bright luster and present a matte color. In contrast, the luster of lead-free tin-copper solder paste shows a certain degree of brightness and looks more attractive. This is also one of the advantages of copper-containing solder paste. However, the luster color of the solder joint does not represent the soldering performance of the solder joint itself.

Fourth, different comprehensive performance: Due to the effect of silver metal, silver-containing solder paste has better and stronger firmness than copper-containing lead-free solder paste, and the solder joints are more secure. Secondly, electrical conductivity is also a very important indicator in solder joints. Silver is a metal with excellent electrical conductivity, so silver-containing solder paste has better electrical conductivity, thermal conductivity, etc. than copper-containing lead-free solder paste. These performances are all beyond the reach of copper-containing lead-free solder paste.

Five. Different costs: Due to the high price of silver metal, silver-containing solder paste is more expensive than lead-free copper-containing solder paste. This is the greatest advantage of copper-containing lead-free solder paste. The higher the silver content in silver-containing solder paste is, the more expensive the cost will be.

Shenzhen JJY Industrial Technology Co., Ltd. mainly engages in:LEDType solder paste, lead-containing solder paste, lead-containing silver solder paste, stainless steel plate type solder pasteSMTManufacturers of solder paste, lead-free flux, no-clean solder wire, lead-free solder wire, leaded solder wire, wave soldering strips, automatic soldering wires, etc.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account