Lead-free medium-temperature solder pasteThere are two kinds of solder pastes: silver solder paste and copper solder paste. And what are the differences between these two kinds of solder pastes? How to choose when in use? Today, the solder paste manufacturer will explain it to everyone:

The differences between silver-containing solder paste and copper-containing solder paste mainly come from the following aspects:

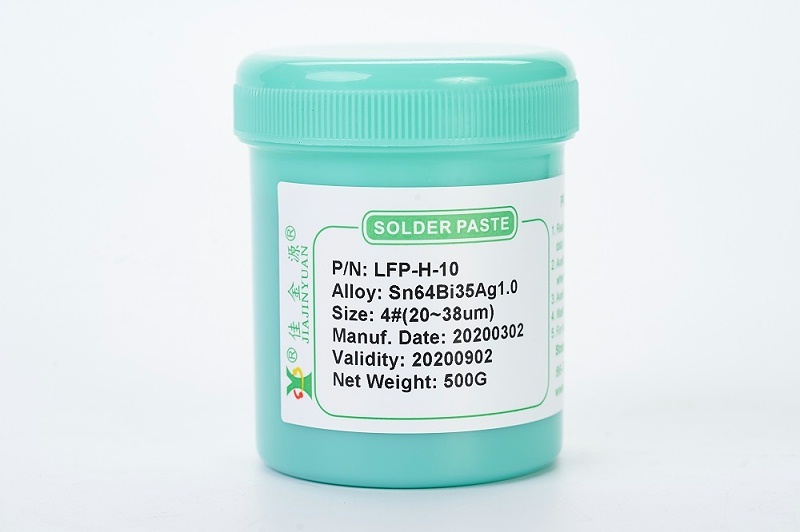

1The alloy compositions of the two are different. The composition of lead-free solder paste containing silver is tin, bismuth and silver, while the alloy composition of lead-free solder paste containing copper is tin, bismuth and copper.

2The melting points of the two are different: with the difference in alloy composition, the melting point of lead-free solder paste containing silver is much lower than that of lead-free solder paste containing copper, and the melting point of silver-containing solder paste is generally172℃The melting point of copper-containing solder paste is170-200℃Between each other.

3The actual test results of the two are different. The solder processing firmness of silver-containing solder paste is weaker than that of copper-containing solder paste.

4The electrical conductivity of the two is different: under the same proportion, the electrical conductivity of silver-containing solder paste is better than that of copper-containing solder paste.

The above is the difference between silver-containing solder paste and copper-containing solder paste. You should decide based on your actual needs. If you need better electrical conductivity, you can choose lead-free solder paste containing silver. If you need better hardness, you can choose lead-free solder paste containing copper.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account