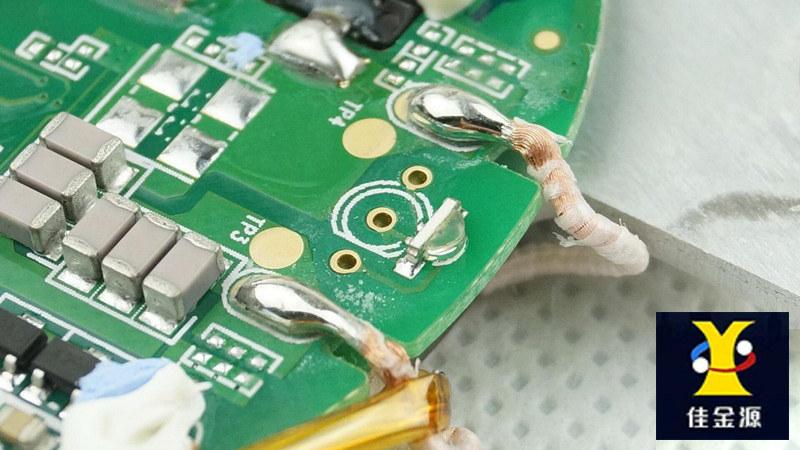

inPCBADuring the processing, some undesirable phenomena may occur after the circuit board is soldered, such as voids (also often referred to as air holes or bubbles).VoidThe most common defective phenomena such as (), which will directly affect the product quality. Therefore, in the daily processing, the causes should be analyzed specifically and the problems solved. Now, let's have Jia JinyuanSolder paste manufacturerI have sorted out the main reasons for the formation of voids at solder joints, hoping it can help everyone solve the problem.

The main reason for the formation of voids at solder joints is that the bubbles produced by the decomposition of organic substances in the flux when heated cannot be discharged in time. After cooling in the solder joints, voids will occur. The influencing factors of solder joint voids are as follows:

1Flux activity. Due to the high-temperature cracking of the organic substances in the flux, the bubbles are difficult to escape, resulting in the gas being trapped in the alloy. If the buoyancy of the gas produced by the organic matter is less than the surface tension of the solder, the gas will be trapped inside the solder joint, thereby forming a vowel phenomenon.

2Welding time.Sn63-Pb37The impregnation time of the solder is very short, approximately0.6sAndSnAgCuThe impregnation time of the solder is approximately1.5sIn these cases, the gases produced by the pyrolysis of organic matter are difficult to escape and will be completely enclosed in the alloy layer.

3Moisture in the solder paste. After the solder paste is taken out of the refrigerator, it should be at room temperature(25℃±3℃)Save at least4Avoid inhaling moisture from the air. Solder paste must be stirred before use. During the manual stirring process, the time should not be too long(about3min-5min)The stirring force should not be too strong. It is recommended to use a centrifuge for stirring. Solder paste should not be left in the air for too long after printing(Generally2Within an hour)Otherwise, excessive water absorption of the solder paste will increase the probability of cavity formation.

4Solder pad oxide.PCBThe higher the degree of oxidation and dirt on the surface of the solder pad, the more it will be after weldingPCBAThe more cavities are produced by the solder joints. The greater the degree of oxidation of the solder pad, the stronger the active agent is needed to deal with the oxide on the surface of the welded object. Solder paste and oxides on the surface of the metal to be welded must be avoided. Otherwise, there is no other way to reduce the formation of cavities.

The above is a brief introduction to some issues related to the formation of voids in solder joints. If you need to know more about our products, please follow JJY Solder Paste Factory and leave a message online to interact with us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account