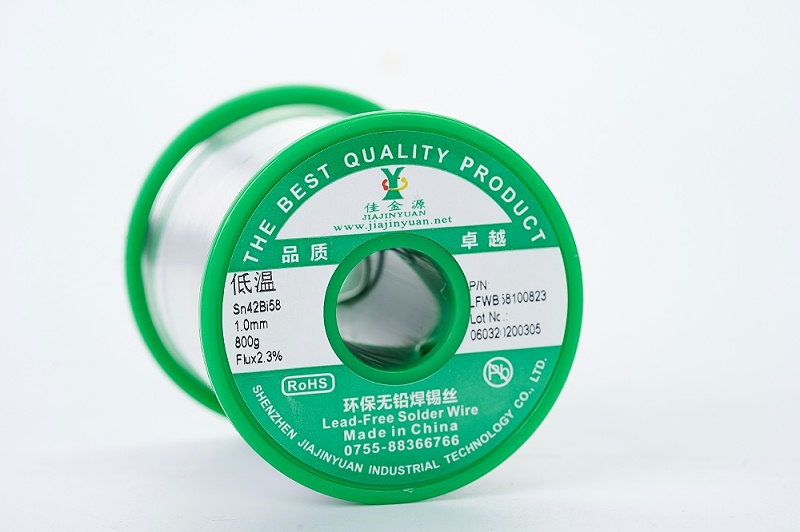

Low-temperature solder pasteProcess application report: The current low-temperature solder paste is generallySn-BiSeries, includingSnBi,SnBiAg,SnBiCuAmong various alloy components, etcSn42Bi58It is an eutectic alloy, and its melting point is138℃The other alloy components all have no eutectic points and their melting points are also different.Sn42Bi58The crystallization of this alloy is in a flaky structure, meaning that the weld points are prone to brittle cracking. Therefore, it is not suitable for products with general strength requirements. After adding the third element, the crystalline structure changes and the strength improves, which can reach a level close toSACThe degree of intensity. But for nowSnBiAgandSnBiCuIt is not widely used in the market, so the price of tin powder is relatively high (here, "high" refers to the processing cost of tin powder). OverallSnBiCuThe price is much lowerSACIt's slightly higher than thatSnBitheSnBiAgThe price is higher because it contains silverSnBiCuIt should be taller. In addition to the price, the cost also involves the issue of energy consumption. Since the furnace temperature for low-temperature solder paste has decreased, the energy consumption will also be reduced accordingly.

Application example of low-temperature solder paste: In a project of a research laboratory and a processing plant, two processing technology requirements were clearly put forward.1The electrical assembly of printed circuit boards is a lead-based reflow soldering method.2It was carried out by DensoPCBAIt is connected to the outer cavity of the metal material and dried and solidified by the flow back welding method. For Customer Bring Production Regulation Our side Carry out first Prenatal processing technology Evaluation .

It is accomplished by using the ultra-low temperature welding methodPCBAThe inner cavity of the assembly is returned to the electric welding and then dried and solidified The prerequisite that must be achieved isPCBAThe surface temperature must be at185 ℃The following The melting point of lead is183 ℃That is, the temperature setting and calibration of the reflux furnace should be carried out on this premise .

Low-temperature solder pasteIt is mainly used for welding radiator modules. LEDWelding, high-frequency welding, etc., among which the most widely used one is LEDIndustry. For this reason, low-temperature solder paste has all the above-mentioned advantages, so it is now used as LEDOne of the most popular solder pastes in the surface mount technology (SMT) industry, and the most important reason is the maturity of its production process. If you want to know more about solder paste, lead-free solder paste, solder paste and other soldering issues, welcome partners to consult Shenzhen JJY Industrial Technology Co., LTD. Let's learn and grow together! The solder wire, solder paste and solder rods of JJY brand are always waiting for partners to come and take them together.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account