In welding work, when confronted with the difficulty of excessive smoke, the key points lie in the following situations, JJYLow-temperature tin wireThe manufacturer will further analyze:

It is related to the specification of flux content and rosin. The more flux there is, the greater the smoke will be. Different types of rosin have different purities and structures, and thus the smoke they release will also be different.

Among fluxes, surfactants can also cause damage. However, due to different levels of focus, the prices of each low-temperature tin wire manufacturer may vary. What needs to be emphasized is the soldering effect, followed by smoke.

It is related to the users, and partners often encounter consumers taking it outTin wireAfterwards, the tin wire was directly melted on the soldering iron tip, generating a considerable amount of smoke. This method of testing the smoke is incorrect. The appropriate approach is to use a smoke box, solder with the same cable diameter and the same length of tin wire, and solder with the same wire of ferrochrome. Pay attention to which one emits more smoke.

Or the consumers arePCBUnder the experience of soldering the same number of points on the circuit board, usually in this situation, partners will control the amount of smoke by the amount of melted tin wire. It is also related to the output power of the electric ferrochrome. For the same type of tin wire, the one with higher power will produce more smoke when soldering than the one with lower power.

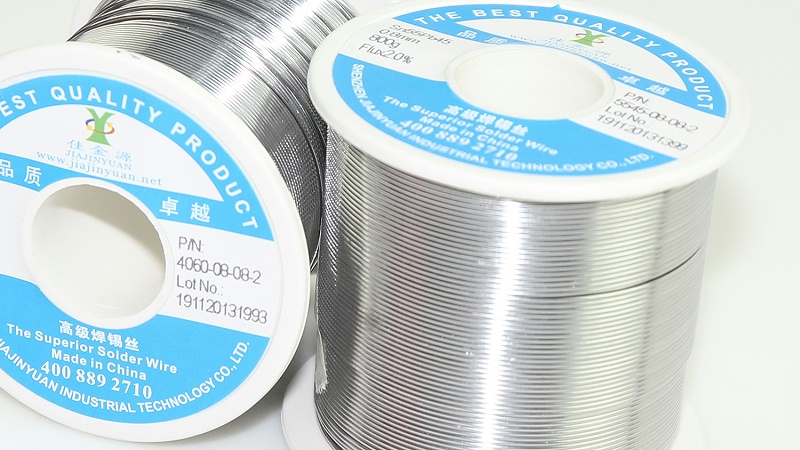

Shenzhen JJY Industrial Technology Co., LTDWith twelve years of product research and development and manufacturing in the field of solder wire production, includingSolder pasteJJY is a reliable manufacturer of solder wire, specializing in the production and research and development of solder wire, solder wire thread (low-temperature solder wire), solder rods, leaded solder paste, etc.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account