Wave soldering is mainly used for making soldering software, while reflow soldering is used for making surface mount components. So will there be any other differences between them? Shenzhen JJYSolder paste manufacturerLet's answer for our partners:

Wave soldering is carried out after meltingSolderingThe formed solder wave peaks are then used to solder the components. On the contrary, reflow soldering takes place in the hot air of a high-temperature area, where the solder is reflow and melted, and only then can the soldering work of components be carried out.

The working processes of wave soldering and reflow soldering are different.

Wave soldering, it isGet it done.After applying the flux, it can enter the preheating area and then proceed to wave soldering for further welding. After welding, the edges and corners must be removed and the defects of the welded products should be inspected. A complete wave soldering can be divided into four major modules, namely "spray, preheating zone, soldering furnace, and cooling zone".

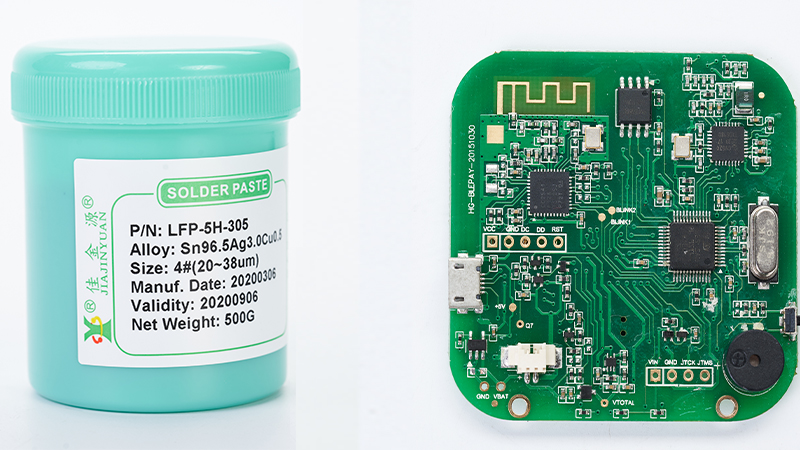

Reflow soldering is done firstDo wellSolder pasteAfter the printing is completed and the components are properly mounted, it can enter the reflow soldering process for soldering. Then, a cleaning and washing operation should be carried out on the soldered products. A complete reflow soldering can be divided into three major area modules, namely "preheating, heating, and cooling".

Shenzhen JJYThe brand's solder paste is suitable for your choice. We offer a solution tailored to your needs. For solder paste manufacturers, choose JJY. Welcome partners to come and consult about other soldering products such as solder wire, solder bar, solder wire, wave solder bar, lead-free solder paste, red glue, etc.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account