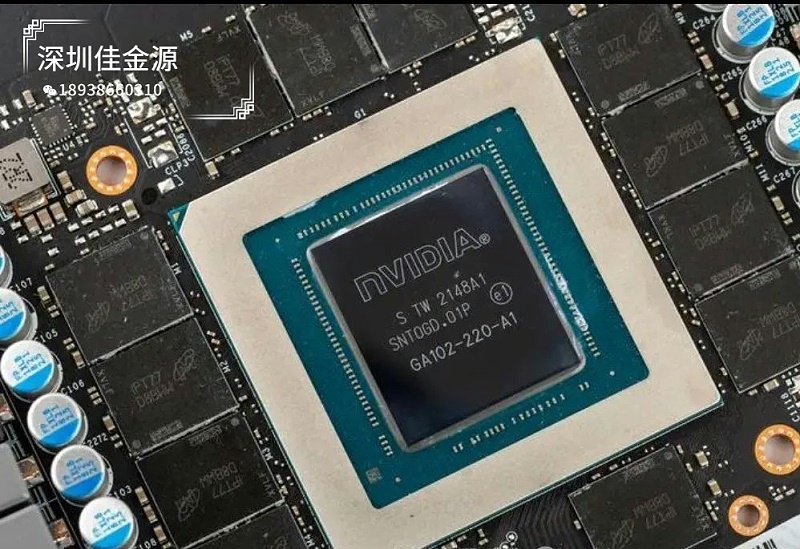

BGADuring the rework process, it is often found that there are incomplete solder joints. Such incomplete solder joints indicate that the volume of the solder joints is insufficientBGAThose that cannot form a reliable connection during weldingBGASolder joint. Its characteristic is that its shape is significantly smaller than that of other solder jointsAXIIt can be easily detected during the inspection. About thisBGAThe problem. The fundamental cause is the solder jointSolder pasteThe deficiency is as follows: Shenzhen JJYSolder paste manufacturerLet's explain what the reasons and solutions are?

I. Causes

BGAAnother common cause of the underfilled solder joints encountered during the maintenance process is the core suction phenomenon of the solder.BGASolder flows into the through hole due to the capillary effect to form information. Surface mount offset or solder printing offset andBGAIf the solder pad vias are not isolated by a solder mask film, it may cause core absorption, resulting in underfullnessBGASolder joint. It is particularly important to note thatBGAIf the solder mask is damaged during the maintenance of components, it will intensify the occurrence of core suction, and further lead to the formation of incomplete solder joints.

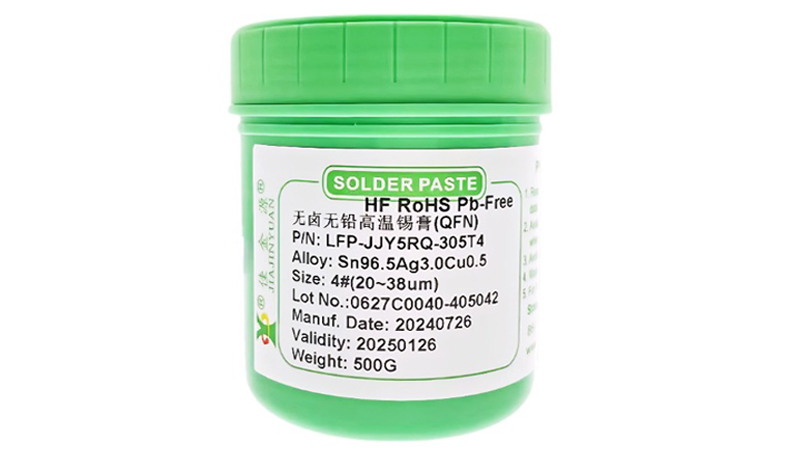

Improper design can also lead to the formation of insufficient solder joints.BGAIf a disk hole is designed on the pad, a large part of the solder paste will flow into the hole. If the amount of solder paste provided at this time is insufficient, it will result in a low levelStandoffSolder joint. The remedial method is to increase the amount of solder paste printed. When designing the steel mesh, the amount of solder paste absorbed by the plate holes should be taken into account. The sufficient amount of solder paste can be ensured by increasing the thickness of the steel mesh or the opening size of the steel mesh. Another solution is to use micro-hole technology instead of the disk hole design scheme, thereby reducing the loss of solder paste.

Another reason for the formation of incomplete solder joints isPCBThe coplanarity between the board and the components is poor. If the amount of solder paste printed is sufficient, butBGAwithPCBDirect inconsistency in the gap can also lead to incomplete solder joints.

Ii. Solutions

Therefore, reduceBGAThe main measures to prevent the formation of incomplete weld points during the welding process are as follows:

1When printing, the amount of solder paste should be sufficient.

2To prevent solder loss, use solder mask to cover the through-hole.

3Operate correctly during the repair stageBGAComponents, avoid damaging the solder mask layer;

4When performing solder paste printing, accurate alignment should be carried out to avoid printing deviations.

5GuaranteeBGAThe accuracy during patching;

6The micro-hole technology is adopted instead of the disk hole design to reduce the loss of solder.

7"Satisfy"PCBandBGATo meet the coplanarity requirements and avoid warping, for instance, appropriate preheating can be adopted during the repair stage.

As a solder paste manufacturer with a history of sixteen years, JJY has always been committed to the research and development, production and sales of solder paste. Our products are of stable quality and have the advantages of no solder connection, no false soldering, no monument erection, etc. The solder joints are bright and full, the soldering is firm, and the electrical conductivity is excellent. If you have any related needs, please feel free to contact us. We will serve you wholeheartedly.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account