inSMTIn the processMedium-temperature lead-free solder pasteIt is a material suitable for surface mount technology. It not only provides reliable electrical performance, but also has good thermal stability and reliability. During the manufacturing process, the furnace temperature is an important parameter, which directly affects the soldering quality of lead-free solder paste. Therefore, it is very important to master the furnace temperature parameters of medium-temperature lead-free solder paste.

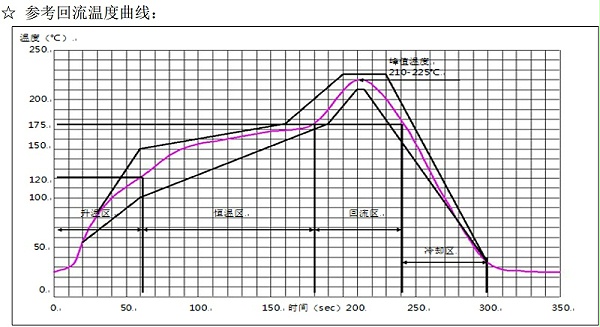

Under normal circumstances, the oven temperature for medium-temperature lead-free solder paste is180-230Between degrees Celsius, but the specific temperature setting should be based on the composition and viscosity of the material.PCBIt is determined by factors such as the design of the plate and the welding process. Generally speaking, the higher the furnace temperature, the better the quality of the weld points. However, excessively high furnace temperatures can also cause cracks and gaps in the weld points, which will reduce the welding quality. Therefore, in practical applications, we need to adjust the parameters according to specific circumstances to achieve the best welding effect.

In addition to the furnace temperature, the baking time is also one of the factors affecting the quality of solder joints. Generally speaking, the baking time for medium-temperature lead-free solder paste is60-120Within seconds, if the time is too short, the strength of the welding point will be insufficient; if it is too long, the welding point will become brittle, making it difficult to meet the actual requirements. Therefore, when soldering medium-temperature lead-free solder paste, we need to set the parameters reasonably according to the actual situation to achieve the best soldering effect.

Overall, the furnace temperature parameters of medium-temperature lead-free solder paste are a very important factor, as they directly affect the soldering process and the quality and thermal stability of lead-free solder paste.

In conclusion, the furnace temperature parameters and baking time of medium-temperature lead-free solder paste are interrelated, and multiple factors need to be comprehensively considered to achieve the best soldering effect. In practical application, we need to adjust the parameters according to different situations and closely monitor the welding quality to improve production efficiency and product quality.

Shenzhen JJY Industrial Technology Co., LTD., dedicated15We have been engaged in the research and development, production and sales of solder for many years, providing customers with a complete set of electronic soldering solutions. For more knowledge about soldering, please keep following JJY Solder Wire Factory and leave a message online to interact with us.