The glossiness of the solder joint isSMT(Surface mount technology)An important indicator for judging the quality of soldering during the surface mount technology (SMT) processing. If the gloss of the solder joints is insufficient, it can affect the connection reliability and performance stability of electronic components. Next up is Shenzhen JJYSolder paste manufacturerLet me introduce the impact to everyoneSMTThe reasons for insufficient gloss of solder joints in surface mount technology (SMT) processing:

1If the tin powder in the solder paste undergoes oxidation, it will affect the gloss of the solder joints.

2The glossiness is also related to whether additives that can produce a matting effect are added to the flux.

3InSMTIn the reflow soldering process of surface mount technology (SMT) processing, the preheating temperature is relatively low, which leads to the retention of residues that are difficult to evaporate on the surface of the solder joints and also affects the gloss of the solder joints.

4After welding is completed, if rosin or resin-like residues remain on the surface of the weld point, it will also affect the gloss of the weld point.

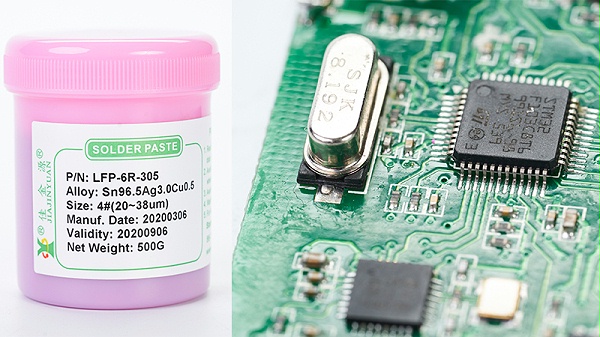

5Apart from the production and processing techniques, the selection of raw materials also has a significant impact on the gloss of the solder joints. For instance, the gloss of the solder joints processed with silver-containing and non-silver-containing solder pastes is different. If there are requirements for the gloss of the solder joints, it is necessary toSMTClear requirements should be put forward before the surface mount technology (SMT) processing is carried out, so as to facilitate the selection of production raw materials and processes.

To sum up, the impactSMTThe reasons for insufficient gloss of solder joints in surface mount technology (SMT) processing include quality issues of the board, improper welding process parameters, improper selection of solder, poor equipment condition, and quality problems of components, etc. To enhance the glossiness of the solder joints, we need to pay attention to the selection of high-quality plates and solders, rationally choose and control the welding process parameters, maintain the good condition of the equipment and accurate calibration, as well as select reliable components.

JJY15We have been dedicated to the research and development, production and sales of solder for many years, providing customers with a complete set of electronic soldering solutions. If you want to learn more about solder paste, please keep following JJY Solder Paste Manufacturer and leave a message online to interact with us.