Generally speaking, the causes of solder beads after reflow soldering are multi-faceted and comprehensive. The printing thickness of solder paste The composition and oxidation degree of solder paste, the production and opening of the template, whether the solder paste has absorbed moisture, the mounting pressure of components, the solderability of components and pads, the setting of reflow soldering temperature, and the influence of the external environment may all be the causes of solder beads. The following is a detailed analysis of the causes and solutions of solder beads from various aspects. There is lead solder pasteThe selection directly affects the welding quality.

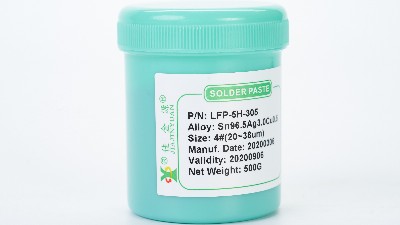

The selection of solder paste also affects the quality of reflow soldering, the content of metals in the solder paste, the content of oxides in the solder paste, and the gold content in the solder pasteThe particle size of the powder and the printing thickness of the solder paste on the printed circuit board both affect the formation of solder beads to varying degrees.

1Metal content in solder paste: The mass ratio of metal content in solder paste is approximately90-91%The volume ratio is approximately50%Left and right. When the metal content increases, the viscosity of the solder paste increases, which can more effectively resist the force generated by vaporization during the preheating process. In addition, the increase in metal content causes the metal powder to be arranged closely, giving it more opportunities to combine and making it less likely to be blown apart during vaporization. The increase in metal content can reduce the tendency of solder paste to sag after printing, and thus it is less likely to form solder beads.

2The content of oxides in solder paste: The content of oxides in solder paste also affects the soldering effect. The higher the content of oxides, the greater the resistance encountered during the bonding process after the metal powder melts. During the reflow soldering stage, the content of oxides on the surface of the metal powder will also increase, which is not conducive to the wetting of the solder paste and leads to the formation of solder beads.

3The particle size of the metal powder in the solder paste: The metal powder in the solder paste is fine spherical, with a diameter of approximately20-75umWhen mounting components with fine and ultra-fine pitches, it is advisable to use solder paste with a smaller particle size of metal powder, approximately20-45umDuring this period, the overall surface area of the welding particles increased significantly due to the reduction of the metal powder. The finer powder has a higher content of oxides, which will alleviate the tin bead phenomenon.

4The printing thickness of solder paste on the printed circuit board: The printing thickness of solder paste is a major parameter in production. The printing thickness of solder paste is usually15-20mmDuring this period, if it is too thick, it will cause the solder paste to collapse and promote the formation of solder beads. When making solder paste printing templates, the size of the solder pads determines the size of the printing holes on the solder paste printing template. Generally, to avoid excessive solder paste printing, we make the size of the printing holes smaller than the corresponding contact area of the solder pads10%. We have carried out such practices, and the results show that this will alleviate the tin bead phenomenon to a considerable extent.

From the above analysis of several aspects, one can roughly understand how to reduce the number of solder beads after reflow soldering. However, reducing the number of solder beads after reflow soldering is also related to the reflow soldering equipment to a certain extent. For those who want to know about solder paste, solder paste, low-temperature solder paste, solder wire and solder bar, welcome to consult ShenzhenJJYIndustrial Technology Co., Ltd. leads everyone to learn and grow together!