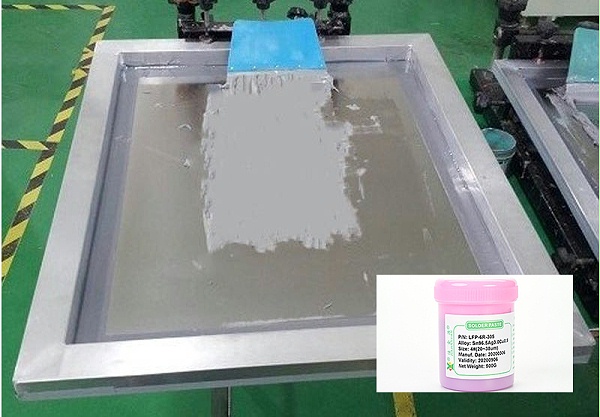

inSMTIn the production of (surface mount technology)Solder pastePrinting, as the first process, its quality is directly related to the success or failure of subsequent welding. During the solder paste printing process,SMTThe selection and preparation of steel mesh are even more crucial. Below, Shenzhen JJY Solder Paste Manufacturer will delve into the discussion of solder paste printingSMTThe specific requirements for steel mesh will help you better master this key process.

I. Steel mesh frame and Tensioning mesh Process

It is recommended to choose steel mesh frames1.5Aluminum alloy material to ensure sufficient strength and stability. When stretching the net, it is recommended to use red glue+By using aluminum tape, ensure that the aluminum frame has uniform contact with the adhesive and apply a layer of protective paint to enhance the surface tension and flatness of the steel mesh. Meanwhile, the distance between the steel mesh and the frame should be controlled at20MM-50MMIn between, to maintain the best printing effect.

Ii. Steel Mesh Material and Opening Design

In terms of the material of steel mesh, stainless steel is especially imported304#Stainless steel is the first choice due to its excellent hardness, elasticity and wear resistance. In addition, the flexibility and adhesion of the two-component epoxy resin also provide good support and protection for the steel mesh. In the design of steel mesh openings, to ensure printing accuracy, the width of the opening area should not be greater than2MM. For pad sizes larger than2MMIn this situation, it is recommended to set it up in the middle0.4MMThe bridge is used to increase the strength of the steel mesh.

Iii. Steel Mesh Marking and Thickness Control

For the convenience of production management, it is recommended to engrave identification information such as the model and time on the steel mesh. Meanwhile, the thickness control of the steel mesh is also the key to ensuring the welding quality. Generally speaking, for a spacing of0.5MMtheQFPandHIP0402The thickness of the components and the mesh plate should be controlled at0.15MM; And for the spacing, it is0.5MMtheQFPandCHIP0603The thickness of the mesh plate for the above components should be increased to0.5MM. In addition, the surface of the steel mesh should be smooth and of uniform thickness to ensure the even distribution of solder paste during the printing process.

The above content is provided by Shenzhen JJY Solder Paste Manufacturer. If you need to know more about itSMTFor knowledge related to surface mount technology (SMT) processing, please feel free to consult JJY16For many years, we have been dedicated to the research and development, production and sales of solder paste, solder wire, solder bar, flux paste and other solder materials, providing customers with a complete set of electronic soldering solutions.