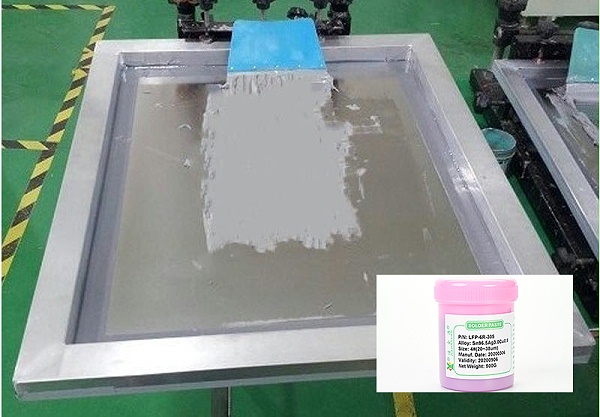

There are many processing plants nowadays,Fully automatic solder paste printers are increasingly being applied in industrial production.Solder pasteSometimes, during the printing process, the steel mesh may get clogged, which greatly affects the work efficiency and makes it impossible to print solder paste normally. So, what are the reasons for the solder paste clogging the steel mesh and how can we avoid this problem? Now, let's share it with you by Shenzhen JJY Solder Paste Manufacturer:

Firstly, during the printing process of the fully automatic solder paste printer, the composition of the solder paste constantly changes, among which the most obvious change is the viscosity. When the temperature is high, the flux evaporates more quickly. When the humidity is high, the water absorption of the solder paste will be more prominent. These are the reasons for the change in the viscosity of the solder paste, thereby affecting its surface tension. The change in tension will directly affect the change in the de-meshing situation, thus causing the steel mesh to be blocked.

Secondly, whether the opening of the solder paste mesh plate in the fully automatic solder paste printing machine is reasonable, the viscosity of the selected solder paste, the size of the solder beads, the material of the squeegee, the pressure during operation, the pressure of the pressing plate and the time of plate removal may all be the reasons for the steel mesh blocking the holes.

Thirdly, the solder paste blocking the steel mesh is related to the internal temperature of the fully automatic solder paste printing machine during operation. The operating environment of the equipment should be taken into consideration.

Fourth,0.4pitchThe openings of the steel mesh are relatively small. If there are many burrs on the edge of the steel mesh, resulting in poor tin plating, it will also cause the mesh frame to block the holes.

Therefore,SMTBefore the fully automatic solder paste printer starts the printing operation, the operator should check the following aspects:

1Select the appropriate scraper: It is usually made of metal or a scraper, depending on the product.

2The printing pressure of the solder paste printer;

3The speed of the squeegee, printing stroke, distance and position of the solder paste printer during printing;

4The demolding method and speed of the printing machine;

5The cleaning cycle of solder paste printers: Generally, fully automatic solder paste printers have options such as dry cleaning, wet cleaning, and vacuum cleaning. The specific cleaning mode and method need to be set according to the product.

6,markThe identification methods of points andstencilPositioning

Steel mesh clogging is only one of the reasons affecting solder paste printing. When using a solder paste printer, we should first ensure the quality and reliability of the equipment to guarantee that the processing quality is reliable. The equipment operates every day, so the daily maintenance and upkeep work is also very important. For more knowledge about soldering, please keep following JJY Solder Paste Manufacturer and leave a message online to interact with us.