Solder pasteIt is a commonly used soldering material in the production of electronic components, and some detailed issues need to be noted when using it. One of them is the warming time. The warm-up time refers to the time required to heat the solder paste from a low-temperature state to the normal operating temperature. If the tempering time is insufficient, it will have a certain impact on the welding process.

Firstly, insufficient warming time will lead to a deterioration in the fluidity of the solder paste. At normal operating temperatures, the fluidity of solder paste is of great significance as it directly affects the quality of soldering. If the fluidity of the solder paste is poor, problems such as false soldering, solder balls, and solder rods may occur during soldering, thereby affecting the performance and lifespan of electronic components.

Secondly, insufficient warming time will also lead to a reduction in the welding contact area. The welding contact area refers to the contact area between the solder joint and the solder pad, which directly affects the strength and stability of the solder joint. If the warming time is insufficient, the solder paste cannot flow fully, which will lead to a reduction in the contact area of the solder joint, thereby affecting the strength and reliability of the solder joint.

Finally, insufficient warming time will also affect the uniformity of welding. The uniformity of welding refers to the degree of uniformity in the distribution of solder joints throughout the entire pad. If the warming time is insufficient, the solder paste cannot flow fully, which will lead to poor uniformity of the solder joints and thus affect the soldering quality.

In conclusion, insufficient warming time will have a negative impact on the fluidity of solder paste, the contact area of the solder joint and the uniformity of the solder joint, thereby affecting the quality of the solder joint and the performance of electronic components. Therefore, when using solder paste, the warming time should be strictly controlled to ensure that the solder paste can be fully warmed up. Only in this way can the welding quality and the performance and lifespan of electronic components be guaranteed.

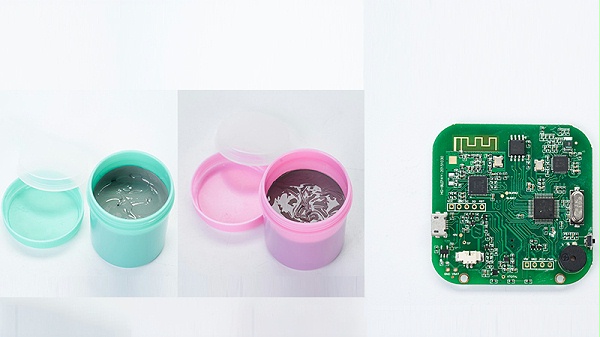

Shenzhen JJY Industrial Technology Co., Ltd. mainly produces and operates: lead-free solder paste, lead-free high-temperature solder paste, lead-free medium-temperature solder paste, lead-free low-temperature solder paste, etc. If you have any needs, please feel free to contact us.