While we are conductingSMTDuring surface mount technology (SMT) processing, leaded solder paste or lead-free high-temperature solder paste, lead-free medium-temperature solder paste, and lead-free low-temperature solder paste are usually used. For cardboard boards, we use medium-temperature solder paste, and forLEDAluminum substrate plate, high powerLEDThen low-temperature solder paste is required, andT5T8Fluorescent lamps require more high-temperature solder paste and less medium-temperature solder paste. ForLEDSoft board sheetMPCFor boards, high-temperature solder paste is generally only used instead of medium and low-temperature solder paste, as medium and low-temperature solder paste is prone to cause component dropping problems. As for heat sinks, low-temperature solder paste is generally used more often, while high-frequency heads require medium-temperature solder paste. Now, the solder paste manufacturer will explain it to you:

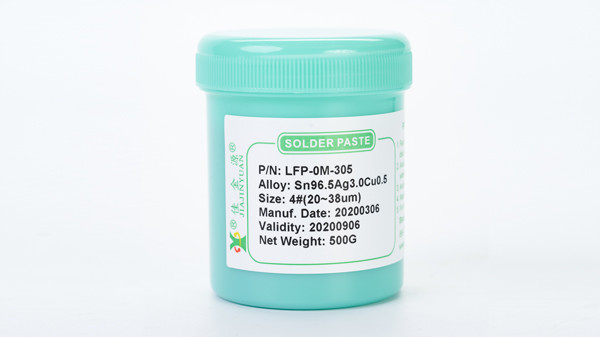

Customers who have used solder paste know that lead-free solder paste can be classified into high-temperature, medium-temperature and low-temperature types. The difference between high-temperature lead-free solder paste, medium-temperature lead-free solder paste and low-temperature lead-free solder paste lies in their melting points. High-temperature lead-free solder paste is composed of tin, silver and copper, while low-temperature ones are tin and bismuth. The melting point of low-temperature is138Celsius, high temperature217~227Celsius. Therefore, if you want to distinguish between these two furnace temperatures, you can place both types of solder pastes on the furnace and set the reflow soldering temperature curve to low-temperature solder paste. If after heating, one type of solder paste drops off components severely or fails to adhere, then this solder paste should be high-temperature solder paste. Because the melting point of high-temperature solder paste is217~227At a certain temperature, this may cause it to fail to melt completely, which in turn leads to the occurrence of component dropping problems.

Whether to use high-temperature solder paste or low-temperature solder paste mainly depends on whether the temperature of some chips cannot be too high when passing through the furnace. If it is too high, bubbles may form or they may fail. However, low-temperature solder paste may cause some problems with the pins after the temperature is generated (relatively high) and some vibrations are added. High-temperature solder paste is generally used in applications that generate a large amount of heat and can withstand high temperaturesSMTSome components generate a relatively large amount of heat. If low-temperature solder paste is used, the solder will melt. Coupled with mechanical vibration and other environmental factors, the components may fall off.

In a high-temperature environment, solder paste is affected by humidity and temperature. Therefore, it is recommended at room temperature23to25Degree, humidity60%Operate in the left and right environments. In this environment, the viscosity of the solder paste can be adjusted to achieve an appropriate viscosity level. If the temperature is too high, the viscosity of the solder paste may become too low. If the temperature is too low, the viscosity of the solder paste may become too high. This will lead to a relatively poor printing effect. Because solder paste is prone to absorbing moisture, if it is used in a high-temperature and humid environment, it will absorb a large amount of moisture, thereby causing solder balls and spatter. After high-temperature lead-free solder paste printing, it is generally reflow within four hours. If left for too long, the solvent will evaporate and the viscosity will decrease, resulting in poor weldability of the parts or the formation of solder balls after absorbing moisture. If at room temperature30Degree, humidity80%When printing solder paste in a high-temperature and high-humidity environment and placing it on one side before reflow, the soldering force will become extremely low. If high-temperature lead-free solder paste is blown by the wind, the solvent will evaporate, causing the viscosity to decrease and the surface to open. Therefore, it is necessary to avoid air conditioners and electric fans blowing directly at the solder paste as much as possible.

These are some relevant contents summarized by solder paste manufacturers regarding the differences between low-temperature solder paste and high-temperature solder paste. You can learn about it when choosing solder paste. JJY Solder Paste Manufacturer mainly deals in lead-free solder paste.SMTSurface mount solder pasteLEDWe are engaged in the research and development, production and supply of solder pastes, lead-free solder wires, rosin solder wires, wave soldering rods, red glue and other solder materials. For more knowledge about electronic soldering, you can follow and contact us. Welcome to interact with us.