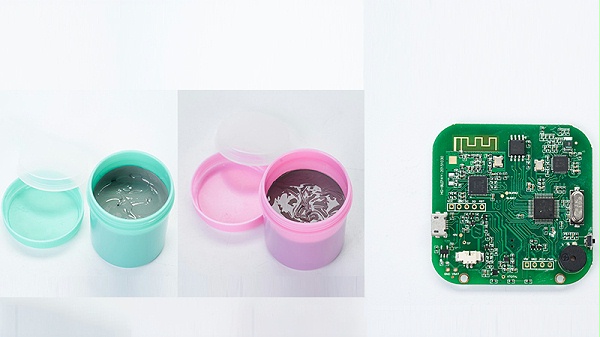

inSolder pasteIn surface mount technology (SMT) processing and welding, whether the solder joints are bright is also a relatively important parameter. After reflow soldering with solder paste, some solder joints are very bright while others are very dark. Why? Could it be that the solder joint that doesn't light up is fake solder paste? The following are some factors that affect the brightness of solder joints:

1When comparing the solder joints of products with no or little silver solder paste and those with a lot of silver solder paste, there will definitely be some differences. This requires suppliers to explain the solder joint indicators to customers when they choose solder paste.

2Excessive reflux time and too low preheating temperature can also cause discoloration of the solder joints. Nitrogen protection can be added. During reflow, the brightness of the solder joint can be improved by increasing the peak temperature and accelerating cooling.

3There is oxidation of the solder powder in the solder paste, which requires the supplier to provide solder paste made from high-purity solder powder. Matting agent is added to the flux itself in the solder paste. Special products are only provided to customers with special requirements.

4After soldering, there are residues of rosin or colored resin on the surface of the solder joint, especially when rosin-type solder paste is selected. Although rosin flux can make the solder joints slightly brighter compared to no-clean flux, the presence of its residues often affects this effect. After welding, cleaning should improve the glossiness of the weld points.

Therefore, it is very necessary to solve the problem of solder paste usage. Through the above four points of introduction, the problem of dull solder joints during the use of solder paste can be solved. As for the solutions to other phenomena, the operator needs to have a better understanding of this aspect of knowledge.