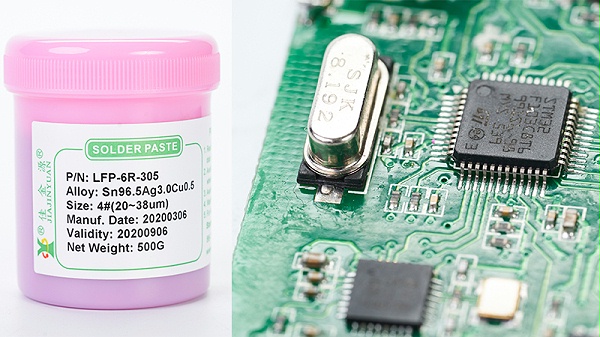

UseLead-free solder pasteAfter soldering, you may find that the circuit board after soldering is not as smooth as you imagined, but rather granular. What could be the reason for this? Today, the solder paste manufacturer will introduce to you the reasons why lead-free solder paste is not smooth after soldering:

The main reasons for the roughness after lead-free solder paste soldering are as follows:

1If the solder paste is preheated for too long, the flux will evaporate, causing the solder paste to be oxidized by the air before it is completely melted. As a result, the soldered product will have particles and be not smooth. So the preheating time should be shortened, usually not exceeding2Minutes.

2If the components are not clean or there are residues on the surface of the circuit board, the solder paste cannot directly contact the circuit board and protrudes. After soldering, it will also produce an uneven phenomenon. In this situation, at the very beginning, check the components and circuit boards to ensure that the surfaces are clear and clean before starting to use them.

3The solder paste is too dry. When the solder paste is dry, the soldering effect will also be poor and it will be granular. Therefore, the wettability of the solder paste must be guaranteed.

The above is the soldering knowledge about lead-free solder paste. I hope it is helpful to you. JJY is a company that conducts mutually beneficial cooperation with electronic raw material manufacturers. Meanwhile, it also produces solder wire, solder bars, solder paste and flux paste for other enterprises. We have a rich variety of successful cases in the research and development of chemical raw materials, and our overall strength builds a high-quality and trustworthy sales market.