Lead-free solder pasteThe process control and manufacturing methods during use. Nowadays, soldering of electronic products is an important production link. Currently, lead-free solder paste products are used, which are divided into low-temperature and high-temperature types, also known as leaded and lead-free. Each type has different manufacturing methods and controls. Now, let's first introduce the manufacturing method of high-temperature solder paste to you by the editor of the solder paste manufacturer:

Semiconductor devices that operate at high temperatures, especially power devicesledFor packaging, high-density integrated circuit packaging, and the assembly of some precision integrated circuits, the second or even third reflow soldering process is carried out using solder paste with a high lead content for soldering. However, lead and its compounds are extremely harmful to human health and cause great pollution to the environment.

The current production processes of fluxes in both leaded and lead-free solder pastes all require100~130℃Even at a slightly higher temperature, heat it to bring the rosin resin to a molten state and dissolve it in an organic solvent(Such as polyols, ethers, etc)Inside. All kinds of powdered activators(Binary to polyorganic acids)It also dissolves into the solvent at this temperature. After the mixture is completely miscible, cool it to room temperature for use. The advantages of this type of technological method are the fast mutual solubility of raw materials and the short production time(General1~1.5An hour is enough.)However, the drawback is that due to the high production temperature, not only does it cause the solvent to evaporate, but worse still, it makes various valuable active ingredients lose their vitality100~130℃It releases activity, decomposes active ions in advance, and reacts with other components at this temperature, greatly losing the flux activity of the finished flux, thereby reducing the flux performance and usage efficiency. Therefore, reducing the production temperature of the flux is the key to ensuring the performance of the flux. At present, the industry mainly reduces the preparation temperature of fluxes by changing the formula components, such as the Chinese patentCN10485871AA halogen-free flux for lead-free tin-bismuth solder paste invented has a melting point of138℃However, during its preparation process, the temperature is as high as180℃Ultimately, it led to the deactivation of a large amount of materials.

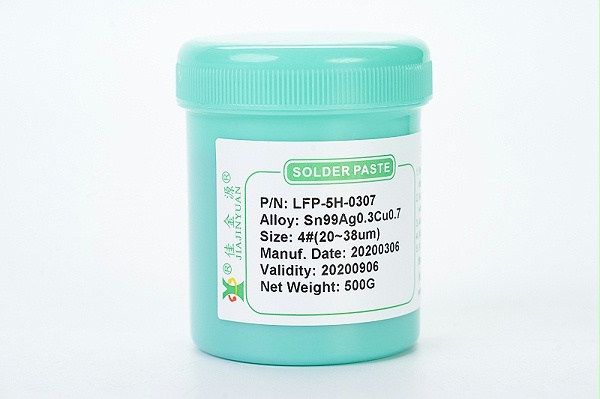

Lead-free high-temperature solder paste, characterized in that it includes the following weight parts of raw materials: paste body10%-15%And tin powder85%-90%;

The paste includes the following weight parts of raw materials: solvent45%-50%Resin30%-35%Active agent5%-8%Stabilizer1%-2%Mold release agent1%-2%Accelerator1%-2%Thixotropic agent2%-3%.

And what is the process control when using high-temperature solder paste? Let's take a look:

Use the solder paste strictly within its validity period. It is usually stored in the refrigerator and should be left at room temperature before use4About an hour(This part is also called thawing)The lid can be opened for use. After use, the solder paste should be stored separately. When using it again, make sure its quality is qualified;

Before production, the operator uses a dedicated stirring rod to stir the solder paste evenly, or uses an automatic mixer to stir it, and regularly spot-tests the viscosity of the solder paste with a viscosity tester;

After the first printed circuit board is printed on the shift of the same day or the equipment is adjusted, the thickness of the printed solder paste should be measured using a solder paste thickness tester. The test points should be selected at the top, bottom, left, right and middle of the test surface of the printed circuit board5Point and record the values. The thickness range of the solder paste should be within the thickness range of the template-10%~+15%;

During the production process, the quality of solder paste printing is inspected100%The main contents of the inspection are whether the solder paste pattern is complete, whether the thickness is uniform, and whether there is any solder paste sharpening phenomenon;

After the shift work is completed, clean the formwork in accordance with the process requirements;

After the printing experiment or printing failure, the solder paste on the printed circuit board should be thoroughly cleaned with an ultrasonic cleaning device and dried to prevent the formation of solder balls after reflow soldering due to residual solder paste on the board when it is used again.

Want to know about solder pasteLead-free solder paste For any soldering issues such as solder paste, we welcome partners to consult Shenzhen JJY Industrial Technology Co., LTD. Let's learn and grow together! The solder wire, solder paste and solder rods of JJY brand are always waiting for partners to come and take them together.