Recently, many customers have been asking why some bubbles appear from time to time at the solder joints when using lead-free solder paste for soldering, and whether it will affect the products. Now let me tell you all that if bubbles appear, it not only endangers the stability of the solder joints but also further increases the probability of component failure,The vast majority of electronic component manufacturers will apply it. The solder paste manufacturer will explain it to you below:

Why do bubbles occur during welding?

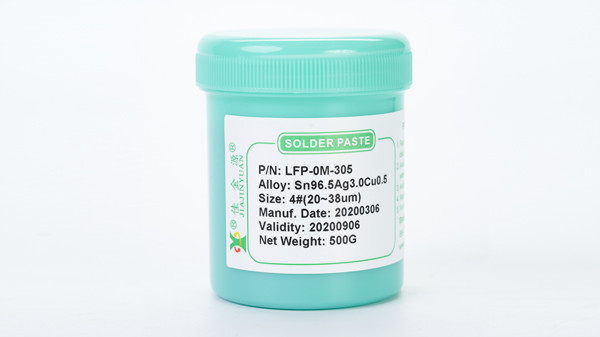

Bubbles in solder joints are usually caused by lead-free flux. Compared with ordinary solder paste, the tin-lead alloy used in lead-free solder paste is also larger and has a higher melting point. Lead-free flux also needs to work at a higher temperature, which greatly increases the chance of volatile substances entering the molten solder during evaporation.

Another reason is that ordinary air reflow soldering equipment cannot create a vacuum environment inside. To effectively remove the air bubbles inside the solder joints from the oxygen in the furnace, and to prevent the oxidation of the solder joints, the reflow soldering furnace is filled with nitrogen, and the nitrogen pressure is higher than the atmospheric pressure, which will cause more air bubbles to form inside the solder joints.

Main reasons:

In fact, the above two reasons are secondary ones. The main reason is caused by the structure of the tin wire. Only by realizing this can the problem be truly solved. The structure of the tin wire is that tin is on the outside, and there is a small tube filled with flux inside the tin wire. When soldering, once the high-temperature tip of the soldering iron touches the solder wire, the flux inside the solder wire melts rapidly, generating a large number of bubbles that burst. Since the solder wire pipeline is sealed, the large number of bubbles produced cause high pressure. When the pressure exceeds the pressure of the pipeline, the solder will be blown away, thus causing a solder explosion.

Based on this reason, we hypothesize that only by making small holes or cutting small seams in the solder wire to change its structure, allowing the solder wire to be breathable during soldering, would there be no solder burst. So we researched and fabricated a specially made machine, using toothed blades and specially made tin wire fixing wheels to press small holes in the tin wire. The soldering experiment has proved that the phenomenon of solder explosion can indeed be largely solved.

Lead-free solder pasteBefore heating, the oxygen in the working area should be evacuated to prevent the formation of an oxide film on the solder during the heating process. The vacuum environment can also increase the wetting area. Of course, apart from the above-mentioned issues that can affect the formation of blisters in lead-free solder paste after use, there are also many small details in our daily work. As long as we pay attention to these in our work, we believe that the occurrence of blisters can be avoided.

Generally, some problems are inevitable during the welding process. Therefore, we still need to be cautious when using it and not be too hasty, which may cause unnecessary incidents. It is recommended to choose lead-free welding when using lead-free technologyRTSThe curve should be adjusted appropriately according to the solder paste material to achieve the best effect and reduce the appearance of bubbles. If you still have any questions, everyone is welcome to consult!