Lead-free solder pasteWhat causes dryness and what are the ways to deal with it? At present, most companies choose lead-free processing technology. As an important part of lead-free processing technology, lead-free environmentally friendly solder paste has increasingly drawn our attention due to its performance characteristics. Now, let's have the editor of JJY explain several reasons for the dry skin to you:

1.Warming up before use:

In order to slow downFLUXThe reaction speed with tin powder can extend the storage time. Solder paste usually needs to be refrigerated.2-10℃Store. Before printing and use, the solder paste should be warmed up at standard room temperature. Standard500gThe solder paste in the container should be warmed up at least2For more than one hour, until the temperature of the solder paste is the same as the ambient temperature. Opening the sealed can lid when the temperature is insufficient will cause the water vapor in the air to condense due to the temperature difference and enter the solder paste, thereby causing it to dry out.

2.Ambient temperature and humidity for use:

The storage temperature of solder paste is2-10℃It should be stored in between, but when in use, the recommended ambient temperature is20-25℃Relative humidity30%-60%. Because usually every time the temperature rises10℃The chemical reaction rate approximately doubles, so excessively high temperatures will increase the evaporation rate of the solvent in the solder pasteFLUXDue to the reaction speed with tin powder, the solder paste is prone to drying out. If the temperature is too low, it will affect the viscosity and expansion of the solder paste, and it is easy to have poor printing. Meanwhile, excessive humidity will also significantly increase the amount of water vapor entering the solder paste. However, too low humidity can also affect the evaporation rate of the solvent in the solder paste.

Generally, adding a certain amount of silver to solder paste can improve the quality of the solder paste and enhance the soldering effect. However, at the same time, it is necessary to avoid losses caused by the scrapping of solder paste and do a good job in the recycling and treatment of solder blocks.

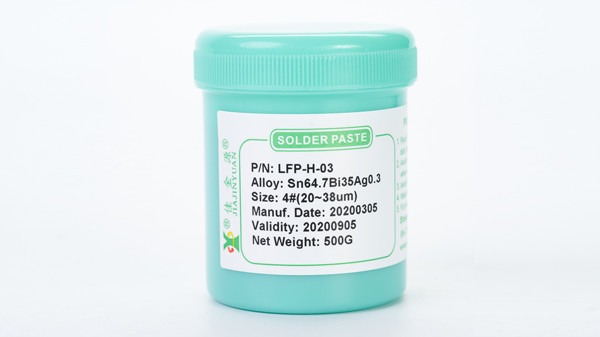

Contain silverLead-free solder pasteWhat has been adopted by a large number of customers is included 0.3 Silver-containing lead-free solder paste, it*Some advantages of low cost and high cost performance have been widely promoted in the market, helping enterprises break free 3.0 The high cost confusion of high-temperature lead-free silver solder paste. Suitable for soldering of general processing and consumer electronic products. Lead-free solder of tin-silver-copper with low silver and low cost*A good choice. Good wettability, heat resistance, electrical conductivity and no residue. The weld points are full and bright, without any poor conditions such as false welding or erect markers. It has moderate viscosity, stability and is suitable for high-speed or manual printing .

The price of silver-containing solder paste is relatively high. If it is scrapped, it will cause considerable loss. Scrapped solder paste can be passed through The recycling and processing of tin blocks for reuse saves costs and avoids waste.

Shenzhen JJY has carried out mutually beneficial cooperation with electronic raw material producers. At the same time, it also produces solder wire, solder bar, solder paste and flux paste for other enterprises. With a rich variety of successful cases in the research and development of chemical raw materials, our overall strength has created a sales market that is of high quality and honest and trustworthy.