ShenzhenLead-free high-temperature solder pasteWhere can I find manufacturers supplying goods ? What do we need to know when choosing JJY lead-free high-temperature solder paste? Below, the editor of JJY has sorted out some knowledge about lead-free high-temperature solder paste for you:

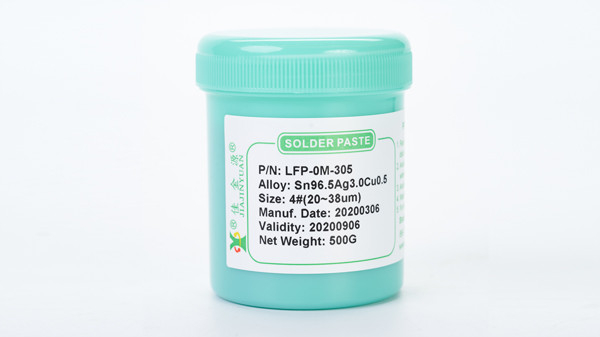

Firstly, lead-free solder paste is classified into high-temperature solder paste, medium-temperature solder paste and low-temperature solder paste based on its melting point. As the name suggests, lead-free high-temperature solder paste is a type of solder paste that can withstand high temperatures. High-temperature solder paste is primarily composed of a paste made of tin-silver-copper alloy components and the corresponding flux. Its melting point is210-227℃Between. The commonly used particle sizes of solder paste include20-38umand25-45umTwo types, viscosity:200Pa.s Left and right.

The solder paste followsSMTA new type of welding material that emerged in response to The Times. Solder paste is a complex management system, which is a paste made by mixing solder wire powder, flux paste and other additives. Solder paste has a certain degree of viscosity at room temperature and can initially bond electronic components to clear positions. At the soldering temperature, along with the evaporation of organic solvents and some food additives, the components to be soldered are electrically soldered together with the pads of the printed circuit board to form a connection.

If the solder paste is not used up on the same day and will not be manufactured again the next day, store it in the refrigerator and mark the time.

In the 20th century70The surface mount technology of the era(Surface Mount TechnologyCommon nameSMT)It refers topcbThe circuit board pads are packaged, printed, and coated with solder paste. Surface mount components are precisely placed onto the pads coated with solder paste. The circuit board is heated according to the specified reflux temperature curve to melt the solder paste. The metal components cool and solidify on the componentspcbThe technology of completing the connection in the metallurgical industry by generating spot welding in the middle of the circuit board. The term "solder paste" is not unfamiliar to employees in the field of solder wire. YesSMTOne of the essential materials for surface mount technology (SMT) production and manufacturing, how is solder paste used? Step: Heat up the solder paste: Solder paste is usually stored in the refrigerator, and the temperature is generally at2-10℃When applying, the solder paste needs to be removed from the freezer and restored to the indoor temperature (approximately)4Hours. Step 2: Mixing of solder paste: Recommended manual mixing time in3-It takes about five minutes for the equipment to mix2-3Minutes. Step 3: Packaging and printing: Stainless steel mesh plate grid packaging and printing. Step 4: Pass through the reflow oven. Step 5: Refrigeration. Step 6: Detect the next process flow.It should be particularly noted that the solder paste that has been opened should be used up as soon as possible under normal circumstances. If this cannot be achieved, the excess solder paste on the steel formwork can be put into an empty earthenware pot after working days, and it will not be used next time. However, used solder paste should not be mixed with unused solder paste in the same bottle, as fresh solder paste is very likely to be contaminated by used solder paste and develop mold.

Want to know aboutSolder pasteFor issues related to lead-free solder paste, solder paste and other soldering, we welcome partners to consult Shenzhen JJY Industrial Technology Co., LTD. Let's learn and grow together! The solder wire, solder paste and solder rods of JJY brand are always waiting for partners to come and take them together.