With the continuous development of society, solder paste products have been widely used. Nowadays, many manufacturers need to use such products. Moreover, it has been constantly upgrading and transforming in line with the pace of technology. Now, let's have the editor of JJY Solder Paste Factory explain some of the functions of this product to you:

Generally, many manufacturers are trying out low-temperature solder paste. However, solder paste manufacturers offer two types of low-temperature solder paste: one is tin-bismuth silver One kind is tin, bismuth and copper . The former is a little more expensive. What are the differences between these two in terms of production?

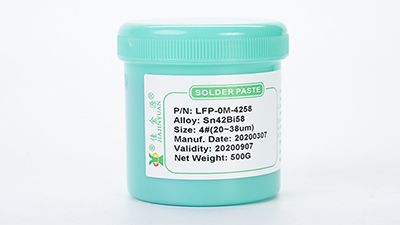

If the aim is only to reduce costs, it is recommended not to try any low-temperature solder paste. Just use the current high-temperature solder paste. If what is being used now is105Or305,(It's probably unlikely), then change it to0307.If what is being used now is0307Either change to another solder paste supplier or negotiate the price with the existing supplier. As for why it is not recommended that you change to low-temperature solder paste, the first reason is the current price ratio of metallic bismuth The price of tin is high20Multiple pieces, no matter what you choose4258+silver Combination or6435+The combination of silver and the price of the raw material from the solder paste supplier are all compared0307The price is high. The only one whose price will be slightly lower is The combination of tin, bismuth and copper. But it makes no sense to switch to this. Why? Tin, bismuth and copper are very difficult to weld together, and this formula doesn't look like it0307So mature, yet highly unstable. There are a large number of remaining problems such as false soldering and poor tinning effect. the loss outweighs the gain. Moreover, the mechanical strength is not so good either. Although it is better than tin, bismuth and silver, it is still better than0307The difference. In addition, let's briefly introduce the origin of medium and low-temperature solder paste: The best welding alloy should be Lead-containing6337The welding effect is the best. However, due to environmental protection reasons, lead-free solder paste has been developed. It's the commonly used one. 0307,105,305,3One of the main models. However, a weakness of the lead-free process is that the welding temperature is high. So, when a part orPCBBoards (such as cardboard) will only be used when they cannot withstand high temperatures or high temperatures will damage parts, and at the same time, they must be environmentally friendlyLow-temperature solder paste. However, the biggest weakness of medium and low-temperature solder paste is that the mechanical strength of the solder joints is low, which leads to the product being easy to produce.

If you need to purchase low-temperature solder paste, you can consult the customer service staff. We will recommend high-quality, cost-effective solder paste products for you. Good quality and excellent service are our advantages! Welcome new and old customers to call for consultation and purchase!