Reflow soldering is mainly applied inSMTIn the manufacturing process, inSMTIn the manufacturing process, the main function of reflow soldering is to attach componentsPCBThe plate is placed in the track of the reflow soldering machine and goes through the processes of heating up, holding at temperature, welding and coolingSolder pasteFrom a paste to a liquid at high temperature, and then to a solid upon cooling, surface mount electronic components are realizedPCBThe function of plate welding.

Reflow soldering machine, also known as reflow soldering machine or reflow soldering machine, all refer to the same equipment. The function of reflow soldering lies in bringingPCBThe board is welded to the components, featuring high production efficiency, few welding defects and stable performance. isPCBAImportant welding equipment in the processing plant.

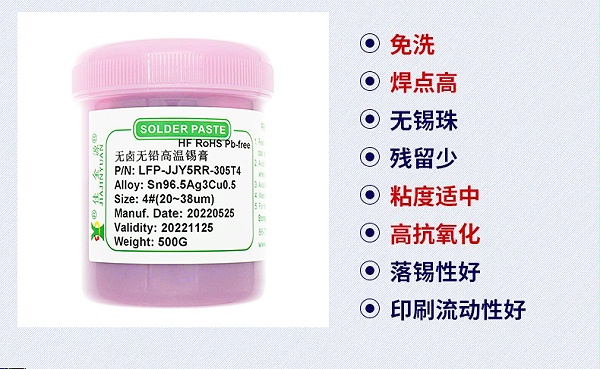

Reflow soldering mainly consists of four temperature zones: the heating zone, the constant temperature zone, the soldering zone, and the cooling zone. This also reflects the change process of the solder paste on the circuit board with the components mounted in the reflow soldering machine. Below, Shenzhen JJY Solder Paste Manufacturer briefly explains the functions of the four temperature zones of the reflow soldering machine.

The main function of reflow soldering

WeldingSMTComponents and ComponentsPCBBoard:

By mounting the componentsPCBThe board is placed in a reflow soldering machine, and the soldering is achieved by the high-temperature melting and cooling process of the solder paste. To enhance production efficiency and welding quality, reflow soldering machines feature high efficiency, low defect rate and stable performancePCBAKey equipment in processing.

The four temperature zones of reflow soldering machines and their functions

Heating zone

1PreheatPCBBoards and components.

2Activate solder paste, volatilize solvents and moisture.

3EliminatePCBInternal stress of the plate.

Insulation zone

1Stabilize the temperature of components to avoid sudden heat damage.

2ReducePCBThe temperature difference between different components on the board.

3Completely evaporate the flux and remove the oxides.

Welding area

1Reach the highest temperature to liquefy the solder paste.

2Wet the pads and component pins to achieve a firm solder joint.

3Control the high-temperature residence time to prevent damage.

Cooling zone

1Rapidly cool and solidify the solder joints.

2Prevent surface roughness and quality problems caused by slow cooling.

In fact, the main function of reflow soldering is to solidify the solder paste through different temperature changes inside the reflow soldering machineSMTComponents are soldered together with the circuit board. Another function is also to solidify, makingsmtThe components are solidified and adhered to the circuit board with red glue, facilitating subsequent wave soldering.

The above content is shared by Shenzhen JJY Solder Paste Manufacturer for you. We hope it will be helpful to you. If you want to know more about solder paste andSMTKnowledge of surface mount technology (SMT) processing. Welcome to leave a message and interact with us!